Anna University Handloom and Textile Technology syllabus of B. Tech. Handloom and Textile Technology Semester IV. In this article, we are glad to provide the syllabus of the Technology of Yarn Spinning.

We aim to provide the following semester TT3454 – Technology of Yarn Spinning syllabus in a detailed manner. We include the appropriate syllabus textbooks and references. Hope this information is useful. Don’t forget to share with your classmates.

If you want to know more about the B. Tech. Handloom and Textile Technology Syllabus is connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B. Tech. Handloom and Textile Technology Syllabus Regulation 2021 Anna University.

Aim Of Objectives:

- To enable the students to learn ring spinning and condensed spinning process.

- To enable the students to understand the yarn plying, twisting, types fancy yarn and method of production.

- To enable the students to learn rotor, friction, air jet, vortex, core and wrap spun yarn production methods.

- To enable the students to learn material passage, draft and production calculation of ring and rotor spinning.

- To enable the students to learn process parameters and production of ring and rotor spun yarn.

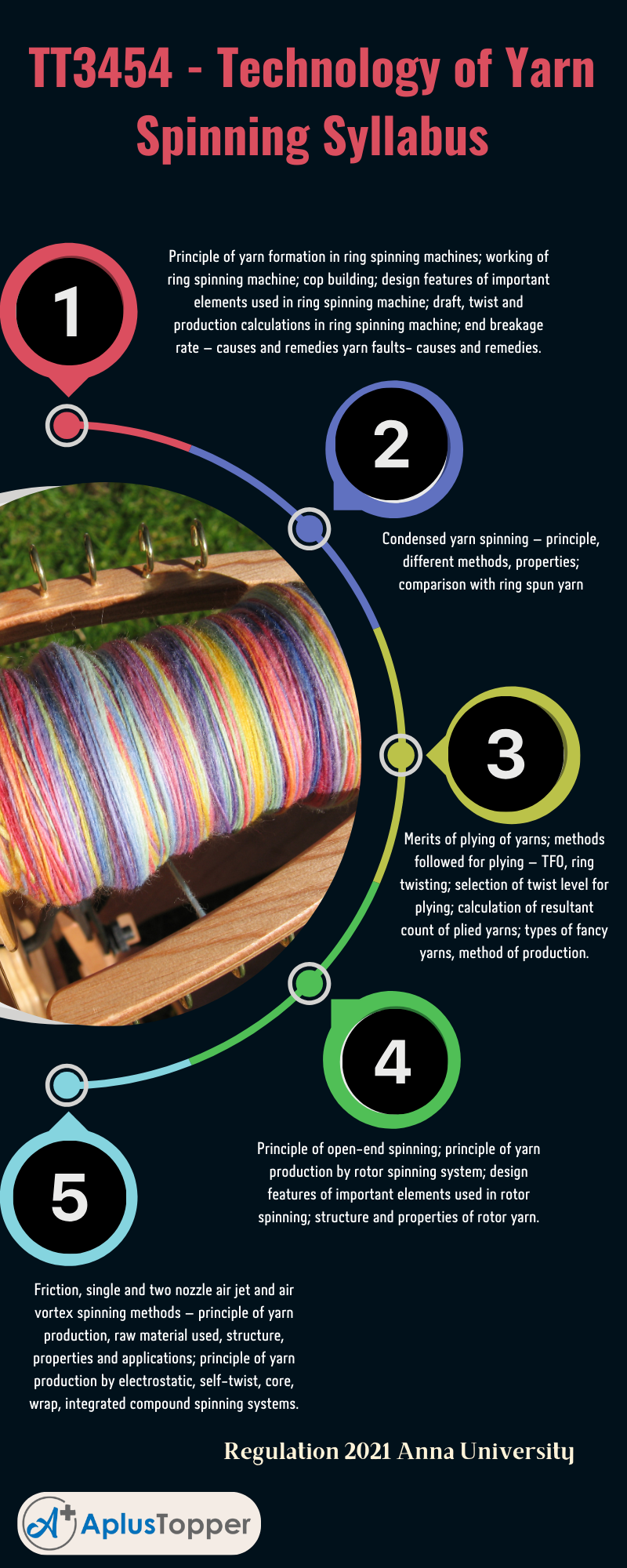

TT3454 – Technology of Yarn Spinning Syllabus

Unit – I: Ring Spinning

Principle of yarn formation in ring spinning machines; working of ring spinning machine; cop building; design features of important elements used in ring spinning machine; draft, twist and production calculations in ring spinning machine; end breakage rate – causes and remedies yarn faults- causes and remedies.

Unit – II: Condensed Yarn Spinning

Condensed yarn spinning – principle, different methods, properties; comparison with ring spun yarn.

Unit – III: Yarn Plying

Merits of plying of yarns; methods followed for plying – TFO, ring twisting; selection of twist level for plying; calculation of resultant count of plied yarns; types of fancy yarns, method of production.

Unit – IV: Rotor Spinning

Principle of open-end spinning; principle of yarn production by rotor spinning system; design features of important elements used in rotor spinning; structure and properties of rotor yarn.

Unit – V: Other Spinning Systems

Friction, single and two nozzle air jet and air vortex spinning methods – principle of yarn production, raw material used, structure, properties and applications; principle of yarn production by electrostatic, self-twist, core, wrap, integrated compound spinning systems.

Text Books:

- Klein W., Vol. 1 -3, “The Technology of Short Staple Spinning”, “A Practical Guide to Opening & Carding” and “A Practical Guide to Combing, Drawing, and Roving frame”, The Textile Institute, Manchester, U.K., 1998.

- Chattopadhyay R. (Ed), Advances in Technology of Yarn Production, NCUTE, IIT Delhi, 2002.

- Klein W., Vol.4 – 5, “A Practical Guide to Ring Spinning”, 1987, and “New Spinning Systems”, 1993, The Textile Institute, Manchester, 1987.

- Gowda R.V.M, “New Spinning Systems”, NCUTE, IIT Delhi, 2003.

References:

- Oxtoby E., “Spun Yarn Technology “, Butterworth Publications, London, 1987

- Lord P.R., “Yarn Production: Science, Technology and Economics”, The Textile Institute, Manchester, 1999

- Shaw J., “Short-staple Ring Spinning, Textile Progress”, The Textile Institute, Manchester, 1982

- Iredale J., “Yarn Preparation: A Handbook “, Intermediate Technology, 1992.

Must Read: