Anna University Handloom and Textile Technology syllabus of B. Tech. Handloom and Textile Technology Semester IV. In this article, we are glad to provide the syllabus of the Knitting Technology.

We aim to provide the following semester TT3452 – Knitting Technology syllabus in a detailed manner. We include the appropriate syllabus textbooks and references. Hope this information is useful. Don’t forget to share with your classmates.

If you want to know more about the B. Tech. Handloom and Textile Technology Syllabus is connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B. Tech. Handloom and Textile Technology Syllabus Regulation 2021 Anna University.

Aim Of Objectives:

- To make the students to understand fundamentals of knitting, types of knitting processes in detail, the functioning of components of knitting machine and knitted fabric structures.

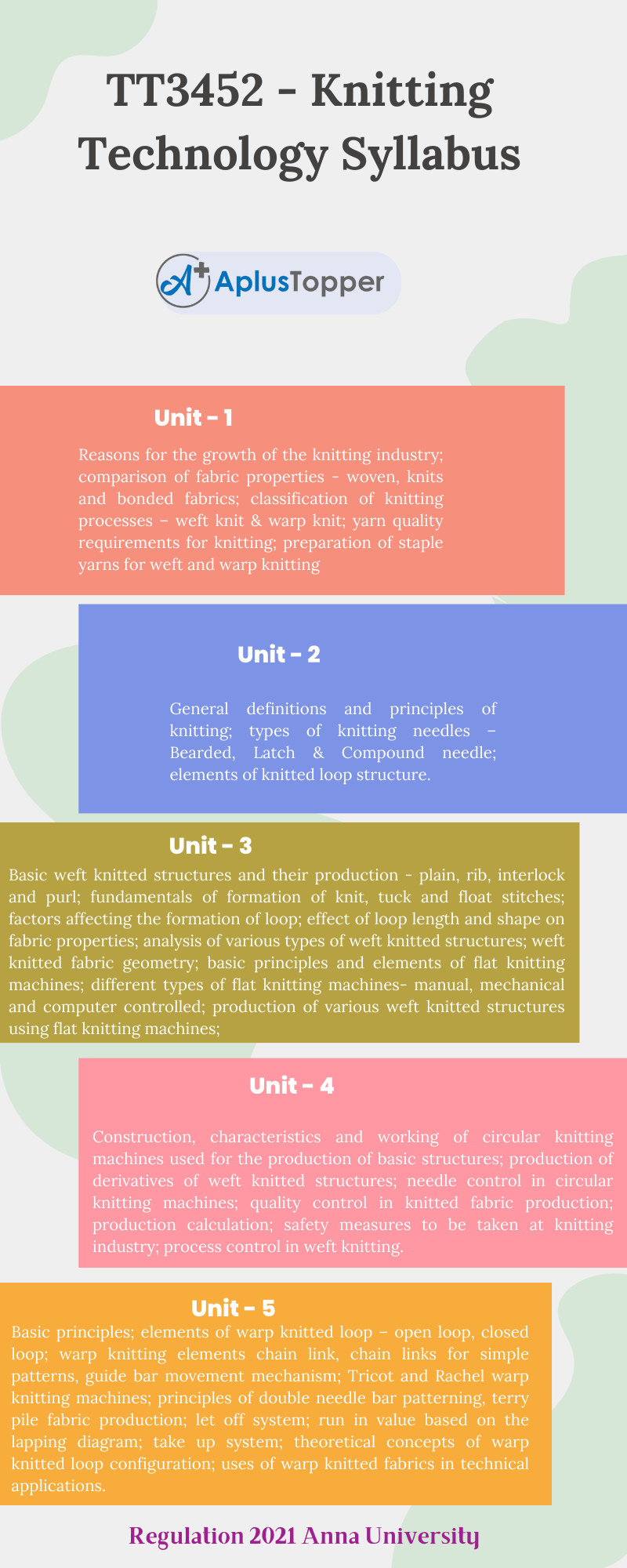

TT3452 – Knitting Technology Syllabus

Unit – I: Introduction

Reasons for the growth of the knitting industry; comparison of fabric properties – woven, knits and bonded fabrics; classification of knitting processes – weft knit & warp knit; yarn quality requirements for knitting; preparation of staple yarns for weft and warp knitting

Unit – II: Fundamentals Of Knitting

General definitions and principles of knitting; types of knitting needles – Bearded, Latch & Compound needle; elements of knitted loop structure.

Unit – III: Weft Knitting

Basic weft knitted structures and their production – plain, rib, interlock and purl; fundamentals of formation of knit, tuck and float stitches; factors affecting the formation of loop; effect of loop length and shape on fabric properties; analysis of various types of weft knitted structures; weft knitted fabric geometry; basic principles and elements of flat knitting machines; different types of flat knitting machines- manual, mechanical and computer controlled; production of various weft knitted structures using flat knitting machines;

Unit – IV: Weft Knitting Machine

Construction, characteristics and working of circular knitting machines used for the production of basic structures; production of derivatives of weft knitted structures; needle control in circular knitting machines; quality control in knitted fabric production; production calculation; safety measures to be taken at knitting industry; process control in weft knitting.

Unit V: Warp Knitting

Basic principles; elements of warp knitted loop – open loop, closed loop; warp knitting elements chain link, chain links for simple patterns, guide bar movement mechanism; Tricot and Rachel warp knitting machines; principles of double needle bar patterning, terry pile fabric production; let off system; run in value based on the lapping diagram; take up system; theoretical concepts of warp knitted loop configuration; uses of warp knitted fabrics in technical applications.

Textbooks:

- Chandrasekhar Iyer, Bernd Mammel and Wolfgang Schach., “Circular Knitting”, Meisenbach GmbH, Bamberg, 1995, ISBN: 3-87525-066-4.

- Spencer D.J., “Knitting Technology”, III Ed., Textile Institute, Manchester, 2001, ISBN: 185573 333 1.

References:

- Ajgaonkar D.B., “Knitting Technology”, Universal Publishing Corporation, Mumbai, 1998, ISBN: 81 -85027-34-X.

- Samuel Raz., “Flat Knitting: The new generation”, Meisenbach GmbH, Bamberg, 1997, ISBN: 3-87525-054-0.

- Samuel Raz., “Warp Knitting production”, MelliandTextilberichte, GmbH, Rohrbacher, 1987, ISBN: 3-87529-022.

- Baneerjee.P.K., “Principles of Fabric Formation”, CRC Press, London, 2014, ISBN Number:13:978-1 -4665-5445-0

- Ray.S.C., “Fundamentals and advances in Knitting Technology”, Woodhead Publishing India Pvt., Ltd, New Delhi. 2011, ISBN: 978-93-80308-16-6.

- Abhijit Majumdar, Apurba Das, R.Alagirusamy and V.K.Kothari., “Process Control in Textile Manufacturing”, Wood Head Publishing Limited, Oxford, 2013, ISBN: 978-0-85709-027-0.

- Gajjap B.J., “Handbook of warp Knitting Technology”, Textile Institute, Manchester, 2004, ISBN: 1 85573 7701.

Related Post:

Must Read: