Anna University Handloom and Textile Technology syllabus of B. Tech. Handloom and Textile Technology Semester III. In this article, we are glad to provide the syllabus of the Preparatory process for woven Fabric Manufacture.

We aim to provide the following semester TT3351 – Preparatory process for woven Fabric Manufacture syllabus in a detailed manner. We include the appropriate syllabus textbooks and references. Hope this information is useful. Don’t forget to share with your classmates.

If you want to know more about the B. Tech. Handloom and Textile Technology Syllabus is connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B. Tech. Handloom and Textile Technology Syllabus Regulation 2021 Anna University.

Aim Of Objectives:

- The main objective of this course is to enable the students to understand the preparatory processes involved in the production of fabrics.

TT3351 – Preparatory process for woven Fabric Manufacture Syllabus

Unit – I: Winding

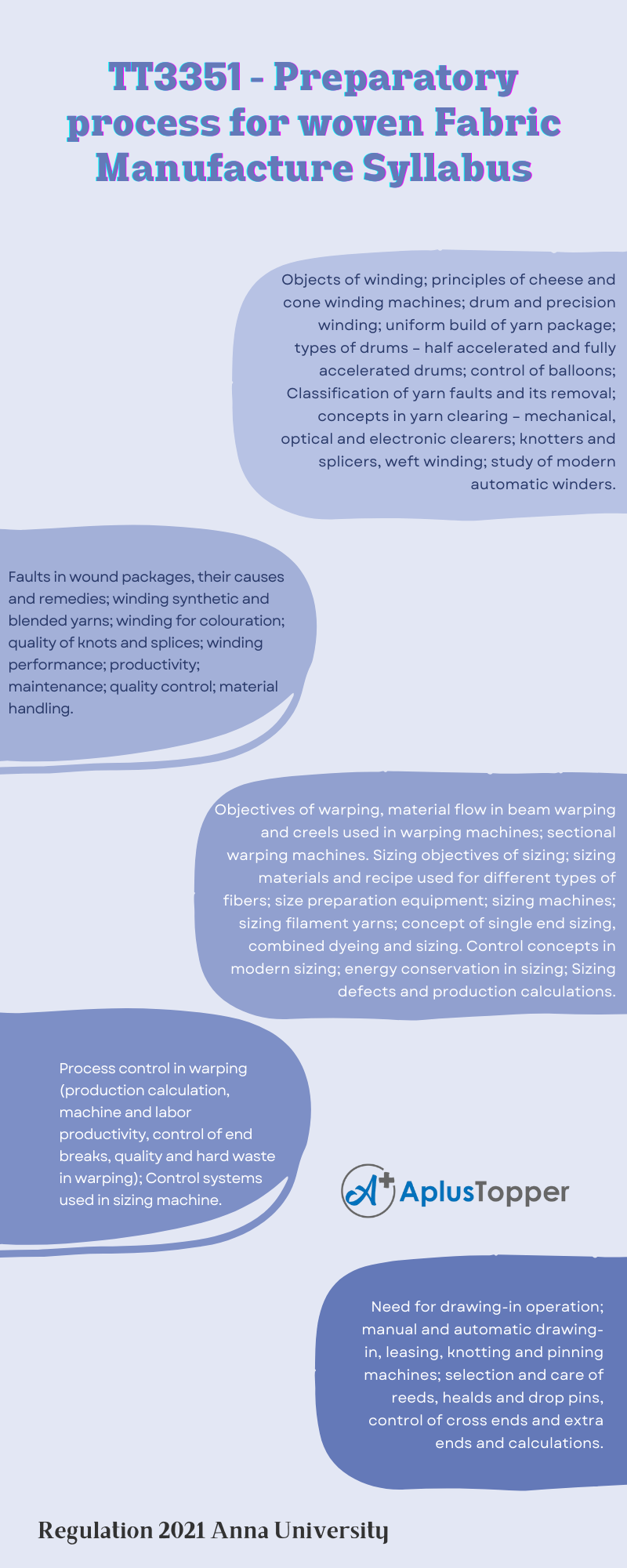

Objects of winding; principles of cheese and cone winding machines; drum and precision winding; uniform build of yarn package; types of drums – half accelerated and fully accelerated drums; control of balloons; Classification of yarn faults and its removal; concepts in yarn clearing – mechanical, optical and electronic clearers; knotters and splicers, weft winding; study of modern automatic winders.

Unit – II: Process Control In Winding

Faults in wound packages, their causes and remedies; winding synthetic and blended yarns; winding for colouration; quality of knots and splices; winding performance; productivity; maintenance; quality control; material handling.

Unit – III: Warping And Sizing

Objectives of warping, material flow in beam warping and creels used in warping machines; sectional warping machines. Sizing objectives of sizing; sizing materials and recipe used for different types of fibers; size preparation equipment; sizing machines; sizing filament yarns; concept of single end sizing, combined dyeing and sizing. Control concepts in modern sizing; energy conservation in sizing; Sizing defects and production calculations.

Unit – IV: Process Control In Warping And Sizing

Process control in warping (production calculation, machine and labor productivity, control of end breaks, quality and hard waste in warping); Control systems used in sizing machine.

Unit V: Drawing- In

Need for drawing-in operation; manual and automatic drawing-in, leasing, knotting and pinning machines; selection and care of reeds, healds and drop pins, control of cross ends and extra ends and calculations.

Text Books:

- Sriramlu P.K., Ajgaonkar D.B. & Talukdar M.K., “Weaving Machines: Mechanisms, Management”, Mahajan Publishers, Ahmedabad, 1998.

- Lord P.R. and Mohammed M.H., “Weaving – Conversion of Yarn to Fabric”, Merrow Publication, 1992.

References:

- John A. Iredale “Yarn Preparation: A Hand Book”, Textile Institute, Manchester, 1992, ISBN: 1853390429

- Lord P. R. and Mohamed M.H., “Weaving: Conversion of Yarn to Fabric”, Merrow, 1992, ISBN: 090409538X

- Ormerod A. and Sondhelm W. S., “Weaving: Technology and Operations”, Textile Institute, 1995, ISBN: 187081276X.

Related Post:

- MA3357 – Probability and Statistical Methods

- HT3301 – Handloom Weaving Technology

- TT3354 – Technology of Pre-Spinning Process

Also Check: