In this article, we are going to discuss the B.Tech Plastics Technology, semester VI, Anna University connected to the regulation 2021 subject syllabus. Let’s see what’s more…

We tried our best to provide the following unit-wise PT3601 – Plastics Product Testing detailed Syllabus. We sum up the appropriate textbooks and references to this page. If you have any doubts regarding the syllabus, you can simply comment below on the following page. Hope this information is useful. Share it with your classmates. Thanks for landing on this page.

If you want to know more about the B.Tech Plastics Technology Syllabus connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.Tech Plastics Technology Syllabus Regulation 2021 Anna University.

Aim of Concept:

- To impart knowledge of National & International standards for testing methods.

- To create the knowledge about the different testing techniques and its basic concepts for evaluating the chemical, mechanical, electrical, optical, thermal, and permanence of plastic materials.

- To enable the students to identify and compare the properties of different plastics materials.

- To enable the students to learn about the property of the plastic material for several applications.

- To learn about failure analysis and destructive testing in polymers

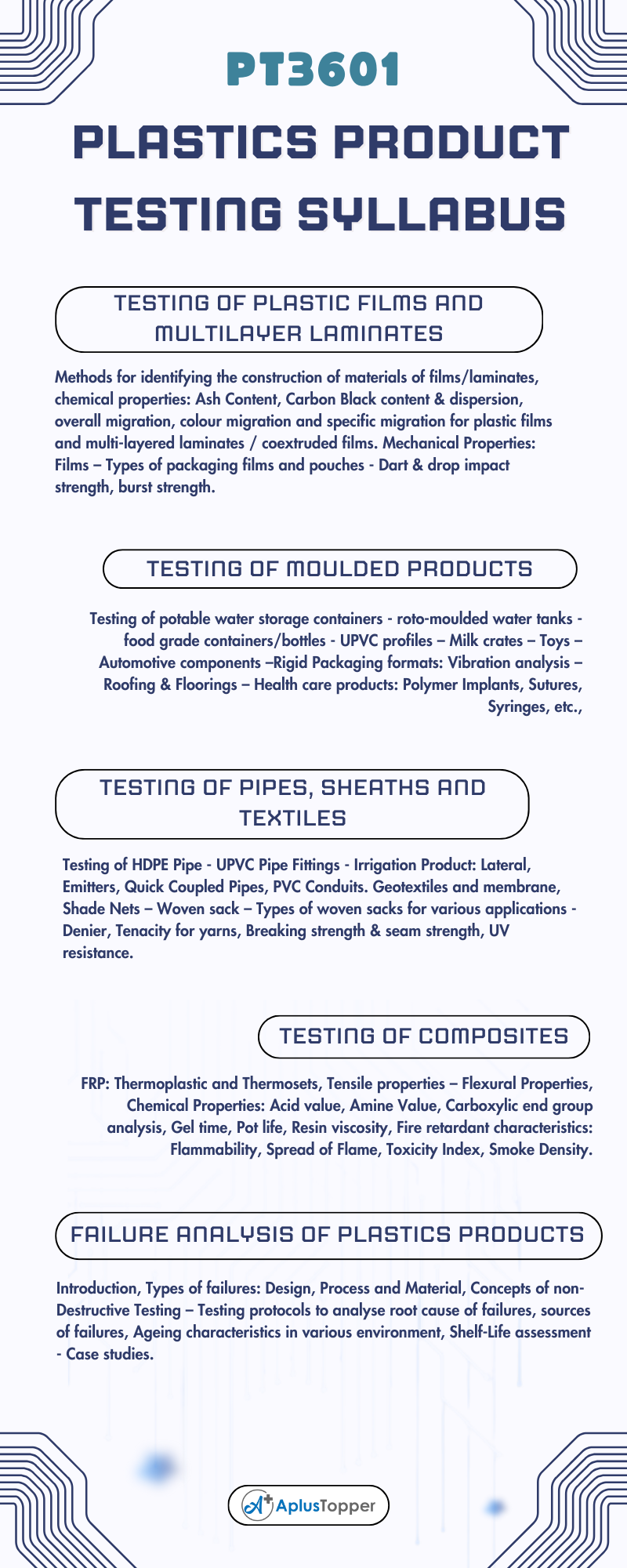

PT3601 – Plastics Product Testing Syllabus

Unit I: Testing Of Plastic Films And Multilayer Laminates

Methods for identifying the construction of materials of films/laminates, chemical properties: Ash Content, Carbon Black content & dispersion, overall migration, colour migration and specific migration for plastic films and multi-layered laminates / coextruded films. Mechanical Properties: Films – Types of packaging films and pouches – Dart & drop impact strength, burst strength.

Unit II: Testing Of Moulded Products

Testing of potable water storage containers – roto-moulded water tanks – food grade containers/bottles – UPVC profiles – Milk crates – Toys – Automotive components –Rigid Packaging formats: Vibration analysis – Roofing & Floorings – Health care products: Polymer Implants, Sutures, Syringes, etc.,

Unit III: Testing Of Pipes, Sheaths And Textiles

Testing of HDPE Pipe – UPVC Pipe Fittings – Irrigation Product: Lateral, Emitters, Quick Coupled Pipes, PVC Conduits. Geotextiles and membrane, Shade Nets – Woven sack – Types of woven sacks for various applications – Denier, Tenacity for yarns, Breaking strength & seam strength, UV resistance.

Unit IV: Testing Of Composites

FRP: Thermoplastic and Thermosets, Tensile properties – Flexural Properties, Chemical Properties: Acid value, Amine Value, Carboxylic end group analysis, Gel time, Pot life, Resin viscosity, Fire retardant characteristics: Flammability, Spread of Flame, Toxicity Index, Smoke Density.

Unit V: Failure Analysis Of Plastics Products

Introduction, Types of failures: Design, Process and Material, Concepts of non-Destructive Testing – Testing protocols to analyse root cause of failures, sources of failures, Ageing characteristics in various environment, Shelf-Life assessment – Case studies.

Text Books:

- Allen; W.S and Baker; P.N, Hand Book of Plastics Technology, Volume 2, Identification,

- Testing & Recycling of Plastics, CBS Publishers and Distributors, New Delhi (2004).

- Brown; Roger P (Ed.), Handbook of Polymer Testing, Marcel Dekker, Inc, New York (1999).

References:

- Brown; Paul F (Ed), Handbook of Plastics Test Methods, Longman Scientific and Technical, Harlow (1988).

- Shah, Vishnu, Handbook of Plastics Testing Technology, John Wiley and Sons, SPE Monograph (1984).

- Blythe; A. R., Electrical Properties of Polymers, Cambridge University Press, Cambridge (1979).

Must Read: