In this article, we are going to discuss the B.Tech Plastics Technology, semester IV, Anna University connected to the regulation 2021 subject syllabus. Let’s see what’s more…

We tried our best to provide the following unit-wise PT3404 – Plastics Mould And Dies Technology detailed Syllabus. We sum up the appropriate textbooks and references to this page. If you have any doubts regarding the syllabus, you can simply comment below on the following page. Hope this information is useful. Share it with your classmates. Thanks for landing on this page.

If you want to know more about the B.Tech Plastics Technology Syllabus connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.Tech Plastics Technology Syllabus Regulation 2021 Anna University.

Aim of Concept:

To impart knowledge on

- Various Molds types, Mold making and Material of mold selection.

- Elements of the mould and manufacturing processes.

- Application of additive manufacturing in mould development

- Advanced measuring instruments for inspection of mold

PT3404 – Plastics Mould And Dies Technology Syllabus

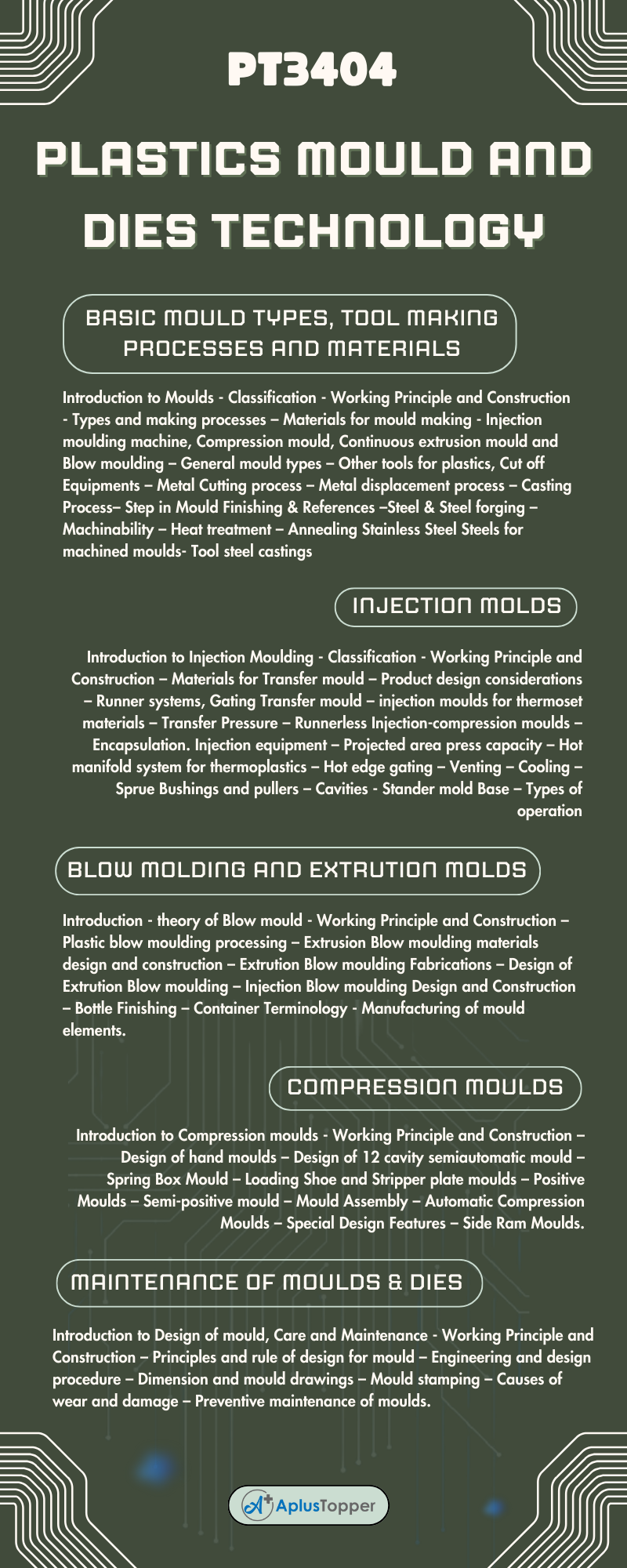

Unit I: Basic Mould Types, Tool Making Processes And Materials

Introduction to Moulds – Classification – Working Principle and Construction – Types and making processes – Materials for mould making – Injection moulding machine, Compression mould, Continuous extrusion mould and Blow moulding – General mould types – Other tools for plastics, Cut off Equipments – Metal Cutting process – Metal displacement process – Casting Process– Step in Mould Finishing & References –Steel & Steel forging – Machinability – Heat treatment – Annealing Stainless Steel Steels for machined moulds- Tool steel castings

Unit II: Injection Molds

Introduction to Injection Moulding – Classification – Working Principle and Construction – Materials for Transfer mould – Product design considerations – Runner systems, Gating Transfer mould – injection moulds for thermoset materials – Transfer Pressure – Runnerless Injection-compression moulds – Encapsulation. Injection equipment – Projected area press capacity – Hot manifold system for thermoplastics – Hot edge gating – Venting – Cooling – Sprue Bushings and pullers – Cavities – Stander mold Base – Types of operation

Unit III: Blow Molding And Extrution Molds

Introduction – theory of Blow mould – Working Principle and Construction – Plastic blow moulding processing – Extrusion Blow moulding materials design and construction – Extrution Blow moulding Fabrications – Design of Extrution Blow moulding – Injection Blow moulding Design and Construction – Bottle Finishing – Container Terminology – Manufacturing of mould elements.

Unit IV: Compression Moulds

Introduction to Compression moulds – Working Principle and Construction – Design of hand moulds – Design of 12 cavity semiautomatic mould – Spring Box Mould – Loading Shoe and Stripper plate moulds – Positive Moulds – Semi-positive mould – Mould Assembly – Automatic Compression Moulds – Special Design Features – Side Ram Moulds.

Unit V: Maintenance Of Moulds & Dies

Introduction to Design of mould, Care and Maintenance – Working Principle and Construction – Principles and rule of design for mould – Engineering and design procedure – Dimension and mould drawings – Mould stamping – Causes of wear and damage – Preventive maintenance of moulds.

Text Books:

- DuBois J. Harry: Plastics Mold Engineering Handbook (English, Paperback, SpringerVerlag New York Inc.4th Edition November 2013

- Klus S DuBois J. Harry, Plastics Mold Engineering Handbook (English, Paperback, Hanser Publishers, NY, 3rd Edition 2013

References:

- Peter Jones, “The Mould Design Guide”, Smithers Rapra Technology Ltd., 2008

- R.G.W.Pye, Injection Mold Design, East West Press Pvt. Ltd., New Delhi.,2000.

- Hajra Choudhary S.K and Hajra Choudhury. AK., “Elements of workshop Technology”, volume II, Media Promoters and Publishers Private Limited, Mumbai, 2010.

- Peter Jones, “The Mould Design Guide”, Smithers Rapra Technology Ltd., 2008.

- W.A.J Chapman, Workshop Technology, Vol I & II, ELBS.

- Herbert Rees, Mold Engineering, Hanser Publishers, NY.,2002.

- George Menges & Paul Mohren, How To Make Injection Molds, Hanser Publishers,2001.

- Douglas M. Bryce, Plastic Injection Molding manufacturing process fundamentals, Society of Manufacturing Engineers, Dearborn, Michigan.,1996.

- Jain R K,” Engineering Metrology”, 19th Edition, Khanna Publishers, 2005.

- Gaylor, Shotbolt and Sharp, Metrology for Engineers, Publisher: O.R.Cassel, London, 1993.

Related Posts On Semester – IV:

- PT3401 – Additives and Compounding

- PT3402 – Fluid Mechanics and Polymer Rheology

- PT3403 – Plastics Materials II

- PT3405 – Plastics Processing

- GE3451 – Environmental Sciences and Sustainability

Must Read: