In this article, we are going to discuss the B.Tech Plastics Technology, semester IV, Anna University connected to the regulation 2021 subject syllabus. Let’s see what’s more…

We tried our best to provide the following unit-wise PT3402 – Fluid Mechanics And Polymer Rheology detailed Syllabus. We sum up the appropriate textbooks and references to this page. If you have any doubts regarding the syllabus, you can simply comment below on the following page. Hope this information is useful. Share it with your classmates. Thanks for landing on this page.

If you want to know more about the B.Tech Plastics Technology Syllabus connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.Tech Plastics Technology Syllabus Regulation 2021 Anna University.

Aim of Concept:

To enable the students to understand the basic concepts of rheology

- To analyze the flow behavior of polymer melts

- To understand the basics of fluid mechanism and to analyze behavior of Newtonian fluids.

- To familiarize with instruments such as orifice meter, Venturi meter and Pitot tube.

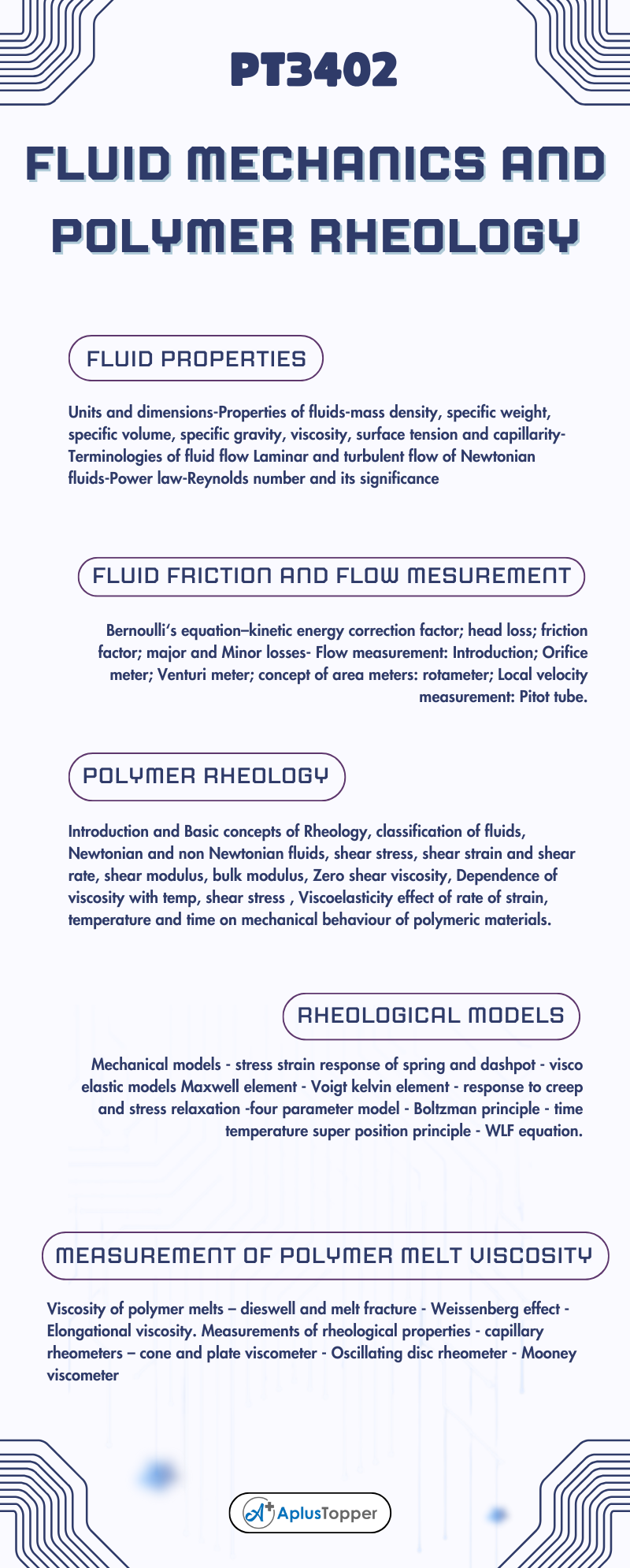

PT3402 – Fluid Mechanics And Polymer Rheology Syllabus

Unit I: Fluid Properties

Units and dimensions-Properties of fluids-mass density, specific weight, specific volume, specific gravity, viscosity, surface tension and capillarity-Terminologies of fluid flow Laminar and turbulent flow of Newtonian fluids-Power law-Reynolds number and its significance

Unit II: Fluid Friction And Flow Mesurement

Bernoulli‘s equation–kinetic energy correction factor; head loss; friction factor; major and Minor losses- Flow measurement: Introduction; Orifice meter; Venturi meter; concept of area meters: rotameter; Local velocity measurement: Pitot tube.

Unit III: Polymer Rheology

Introduction and Basic concepts of Rheology, classification of fluids, Newtonian and non Newtonian fluids, shear stress, shear strain and shear rate, shear modulus, bulk modulus, Zero shear viscosity, Dependence of viscosity with temp, shear stress , Viscoelasticity effect of rate of strain, temperature and time on mechanical behaviour of polymeric materials.

Unit IV: Rheological Models

Mechanical models – stress strain response of spring and dashpot – visco elastic models Maxwell element – Voigt kelvin element – response to creep and stress relaxation -four parameter model – Boltzman principle – time temperature super position principle – WLF equation.

Unit V: Measurement Of Polymer Melt Viscosity

Viscosity of polymer melts – dieswell and melt fracture – Weissenberg effect – Elongational viscosity. Measurements of rheological properties – capillary rheometers – cone and plate viscometer – Oscillating disc rheometer – Mooney viscometer

Text Books:

- Cogswell, Polymer melt rheology, Woodhead Publishing Ltd, 1994.

- R.J. Crawford, Plastics Engineering, Butterworth – Heinemann, Oxford, 2002, 3rd edition

- Dr. R. K. Bansal, “A Textbook of Fluid Mechanics and Hydraulic Machines”, 9th edition, 2017

References:

- P.N.Cogswell, Polymer Melt Rheology, A guide for Industrial Practice, George Godwin,1981.

- Richard C. Progelh of and James L. Throne, Polymer Engineering Principles, Hanser Publishers, New York, 1998.

- John M. Dealy and Kurt F. Wissburn, Melt rheology and its role in plastics processing, Chapman, London, Oct 3rd, 2013.

- R.S. Lenk, Polymer Rheology, Applied Science, London, 2012.

- J.D. Ferry, Viscoelastic Properties of Polymers, John Wiley & Sons, New York, 1986.

- Chang Dae Han. Rheology in Polymer Processing, Academic Press, New York, 1976

Related Posts On Semester – IV:

- PT3401 – Additives and Compounding

- PT3403 – Plastics Materials II

- PT3404 – Plastics Moulds and Dies Technology

- PT3405 – Plastics Processing

- GE3451 – Environmental Sciences and Sustainability

Must Read: