Engineering Metrology deals with the semester V subject of Anna University B.E Production Engineering syllabus. In this article, we try to provide the unit-wise syllabus for academic purposes in one place.

We started to analyze the situation of students who are often confused about the syllabus. What are the topics do they include in the syllabus? In this article, you can simply find the detailed syllabus of the semester V PR3501 – Engineering Metrology. I hope this information is useful. We also provide the required books and references regarding the subject especially.

If you want to know more about the syllabus of B.E. Production Engineering and Management connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.E. Production Engineering and Management Syllabus Regulation 2021 Anna University.

Aim Of Concept:

- To understand the concept of engineering metrology.

- To familiarize the metrology instruments used for linear and angular measurements.

- To learn about the surface texture and measuring instruments.

- To learn about the metrology of screw threads and gears.

- To introduce the concepts of Laser and computer applications in metrology.

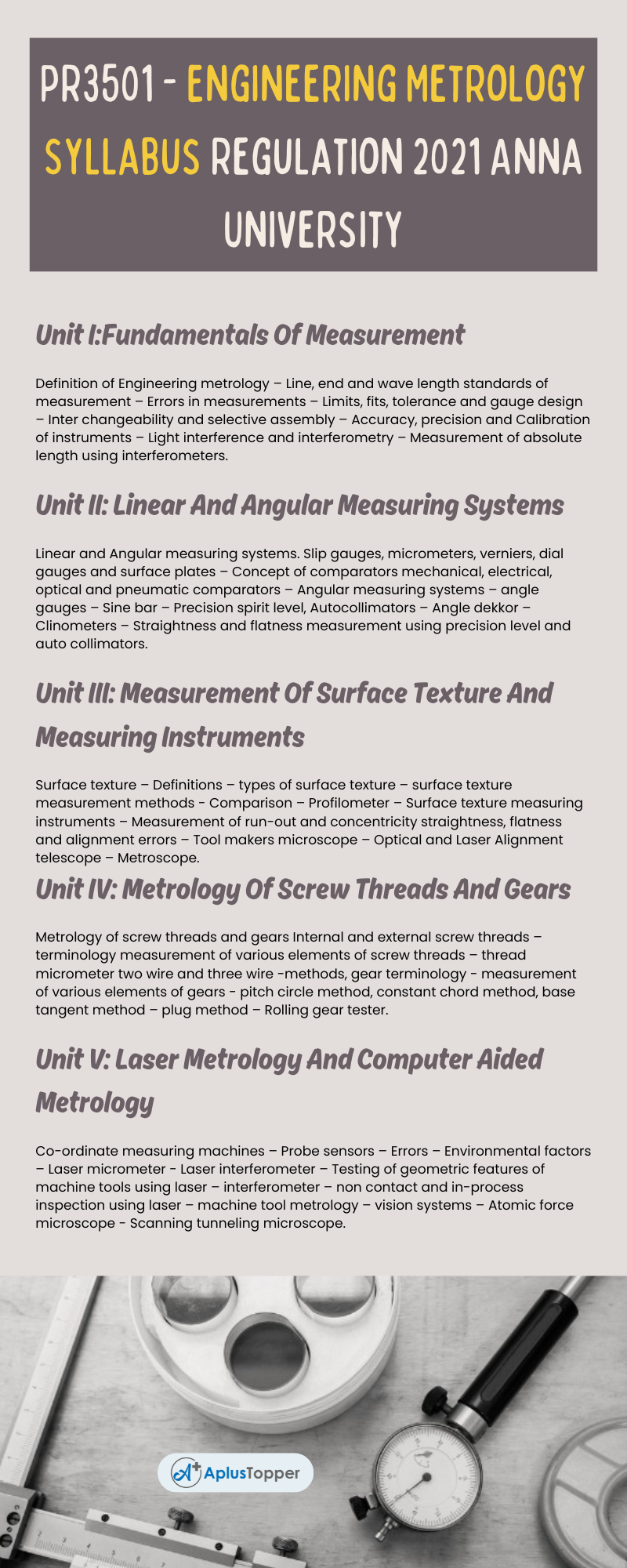

PR3501 – Engineering Metrology Syllabus

Unit I: Fundamentals Of Measurement

Definition of Engineering metrology – Line, end and wave length standards of measurement – Errors in measurements – Limits, fits, tolerance and gauge design – Inter changeability and selective assembly – Accuracy, precision and Calibration of instruments – Light interference and interferometry – Measurement of absolute length using interferometers.

Unit II: Linear And Angular Measuring Systems

Linear and Angular measuring systems. Slip gauges, micrometers, verniers, dial gauges and surface plates – Concept of comparators mechanical, electrical, optical and pneumatic comparators – Angular measuring systems – angle gauges – Sine bar – Precision spirit level, Autocollimators – Angle dekkor – Clinometers – Straightness and flatness measurement using precision level and auto collimators.

Unit III: Measurement Of Surface Texture And Measuring Instruments

Surface texture – Definitions – types of surface texture – surface texture measurement methods – Comparison – Profilometer – Surface texture measuring instruments – Measurement of run-out and concentricity straightness, flatness and alignment errors – Tool makers microscope – Optical and Laser Alignment telescope – Metroscope.

Unit IV: Metrology Of Screw Threads And Gears

Metrology of screw threads and gears Internal and external screw threads – terminology measurement of various elements of screw threads – thread micrometer two wire and three wire -methods, gear terminology – measurement of various elements of gears – pitch circle method, constant chord method, base tangent method – plug method – Rolling gear tester.

Unit V: Laser Metrology And Computer Aided Metrology

Co-ordinate measuring machines – Probe sensors – Errors – Environmental factors – Laser micrometer – Laser interferometer – Testing of geometric features of machine tools using laser – interferometer – non contact and in-process inspection using laser – machine tool metrology – vision systems – Atomic force microscope – Scanning tunneling microscope.

Text Books:

- Jain. R. K., “Engineering Metrology”, Khanna Publishers, 2021.

- Raghavendra N. V. and Krishnamurthy. L, “Engineering Metrology and Measurements”, Oxford University Press, 2013.

- Rajput R.K., “Engineering Metrology and Instrumentation”, 5th edition, Kataria and Sons Publishers, 2013.

References:

- Gupta. I. C., “A Text book of Engineering Metrology”, 7th edition, Dhanpat Rai and Sons, 2012.

- Gayler G. N. and Shotbolt C. R., “Metrology for Engineers”, 5th edition, ELBS, 2000.

- “ASTME Hand book of Industrial Metrology”, Prentice Hall of India Limited, 2002.

Related Posts on Semester – V:

Must Read For More: