Non-destructive Evaluation of Materials is the subject of semester VII of Anna University B.E Material Science And Engineering Syllabus. In this article, we are glad to provide the syllabus of the non-destructive evaluation of materials part of Semester VII Subjects in the first-year course.

We intend to provide the subject code ML3701 – Non-destructive Evaluation of Materials syllabus based on regulation 2021 by Anna University. You can get an idea of the topics in the syllabus of non-destructive evaluation of materials. We hope that the absolute idea on the syllabus will assist the students in avoiding confusion of revision according to weightage. We also include required textbooks and references. If you require anything regarding the syllabus you can comment in the below section. Hope you like this information. Don’t forget to share.

If you want to know more about the syllabus of B.E. Material Science And Engineering connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.E. Material Science And Engineering Syllabus Regulation 2021 Anna University.

Aim Of Objectives:

The main learning objective of this course is to prepare students for:

- Understanding the importance of NDT in quality assurance.

- Acquiring knowledge on the basic principles of various NDT techniques, its applications, limitations, codes and standards.

- Equipping themselves for having proper competencies to locate a flaw in various materials, products.

- Getting ready to use NDT techniques for in-situ applications too.

- Selecting the right NDT technique for a given application.

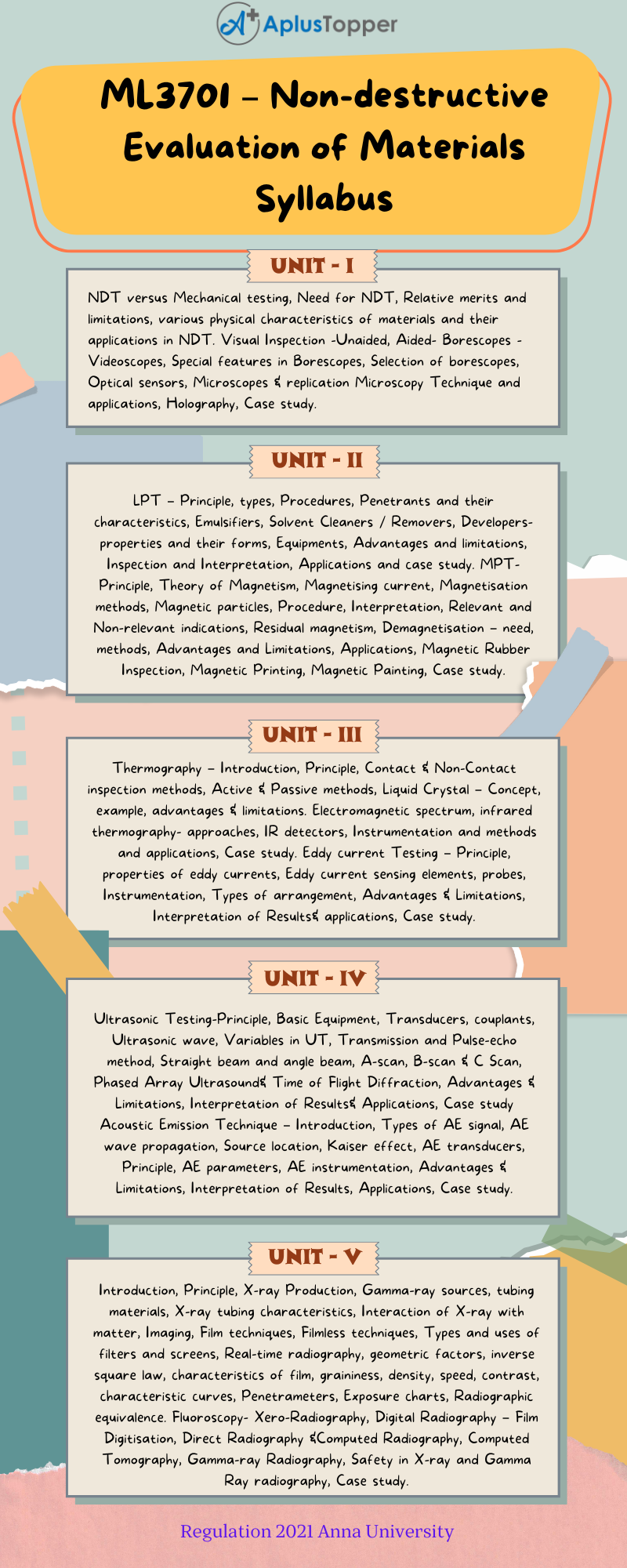

ML3701 – Non-destructive Evaluation of Materials Syllabus

Unit – I: Introduction & Visual Inspection Methods

NDT versus Mechanical testing, Need for NDT, Relative merits and limitations, various physical characteristics of materials and their applications in NDT.

Visual Inspection -Unaided, Aided- Borescopes -Videoscopes, Special features in Borescopes, Selection of borescopes, Optical sensors, Microscopes & replication Microscopy Technique and applications, Holography, Case study.

Unit – II: Liquid Penetrant Testing& Magnetic Particle Testing

LPT – Principle, types, Procedures, Penetrants and their characteristics, Emulsifiers, Solvent Cleaners / Removers, Developers- properties and their forms, Equipments, Advantages and limitations, Inspection and Interpretation, Applications and case study.

MPT-Principle, Theory of Magnetism, Magnetising current, Magnetisation methods, Magnetic particles, Procedure, Interpretation, Relevant and Non-relevant indications, Residual magnetism, Demagnetisation – need, methods, Advantages and Limitations, Applications, Magnetic Rubber Inspection, Magnetic Printing, Magnetic Painting, Case study.

Unit – III: Thermography & Eddy Current Testing

Thermography – Introduction, Principle, Contact & Non-Contact inspection methods, Active & Passive methods, Liquid Crystal – Concept, example, advantages & limitations. Electromagnetic spectrum, infrared thermography- approaches, IR detectors, Instrumentation and methods and applications, Case study.

Eddy current Testing – Principle, properties of eddy currents, Eddy current sensing elements, probes, Instrumentation, Types of arrangement, Advantages & Limitations, Interpretation of Results& applications, Case study.

Unit – IV: Ultrasonic Testing & Acoustic Emission Testing

Ultrasonic Testing-Principle, Basic Equipment, Transducers, couplants, Ultrasonic wave, Variables in UT, Transmission and Pulse-echo method, Straight beam and angle beam, A-scan, B-scan & C Scan, Phased Array Ultrasound& Time of Flight Diffraction, Advantages & Limitations, Interpretation of Results& Applications, Case study

Acoustic Emission Technique – Introduction, Types of AE signal, AE wave propagation, Source location, Kaiser effect, AE transducers, Principle, AE parameters, AE instrumentation, Advantages & Limitations, Interpretation of Results, Applications, Case study.

Unit – V: Radiography

Introduction, Principle, X-ray Production, Gamma-ray sources, tubing materials, X-ray tubing characteristics, Interaction of X-ray with matter, Imaging, Film techniques, Filmless techniques, Types and uses of filters and screens, Real-time radiography, geometric factors, inverse square law, characteristics of film, graininess, density, speed, contrast, characteristic curves, Penetrameters, Exposure charts, Radiographic equivalence. Fluoroscopy- Xero-Radiography, Digital Radiography – Film Digitisation, Direct Radiography &Computed Radiography, Computed Tomography, Gamma-ray Radiography, Safety in X-ray and Gamma Ray radiography, Case study.

Text Books:

- ASM Metals Handbook, “Non-Destructive Evaluation and Quality Control”, American Society of Metals, Metals Park, Ohio, USA, 2000, Volume-17.

- Paul E Mix, “Introduction to Non-destructive testing: a training guide”, Wiley, 2nd edition New Jersey, 2005.

References:

- ASNT, American Society for Non-Destructive Testing, Columbus, Ohio, NDT Handbook, Vol. 1, Leak Testing, Vol. 2, Liquid Penetrant Testing, Vol. 3, Infrared and Thermal Testing Vol. 4, Radiographic Testing, Vol. 5, Electromagnetic Testing, Vol. 6, Acoustic Emission Testing, Vol. 7, Ultrasonic Testing.

- Baldev Raj, T.Jayakumar, M.Thavasimuthu “Practical Non-Destructive Testing”, Narosa Publishing House, 2009.

- Charles, J. Hellier,“ Handbook of Non-destructive evaluation”, McGraw Hill, New York 2001.

- G. Gaussorgues, “Infrared Thermography”, Chapman & Hall, University Press, Cambridge, 1994.

- Ravi Prakash, “Non-Destructive Testing Techniques”, New Age International Publishers, 1st revised edition, 2010.

Related Posts Of Semester – VII:

Must Read: