Non-ferrous metallurgy is the subject of semester V of Anna University B.E Material Science And Engineering Syllabus. In this article, we are glad to provide the syllabus of the non-ferrous metallurgy part of Semester V Subjects in the first-year course.

We intend to provide the subject code ML3502 – Non-Ferrous Metallurgy syllabus based on regulation 2021 by Anna University. You can get an idea of the topics in the syllabus of the non-ferrous metallurgy. We hope that the absolute idea on the syllabus will assist the students in avoiding confusion of revision according to weightage. We also include required textbooks and references. If you require anything regarding the syllabus you can comment in the below section. Hope you like this information. Don’t forget to share.

If you want to know more about the syllabus of B.E. Material Science And Engineering connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.E. Material Science And Engineering Syllabus Regulation 2021 Anna University.

Aim Of Objectives:

The main learning objective of this course is to prepare students for:

- Understanding the structure, property relations of nonferrous alloys with special emphasis on engineering applications.

- Gaining knowledge on the important alloys used for critical applications.

- Having an insight on the phase diagrams of industrially relevant portions of some important alloys.

- Acquiring knowledge on the selection of suitable non-ferrous alloy for a given application.

- Being well versed with the properties and applications of precious metals.

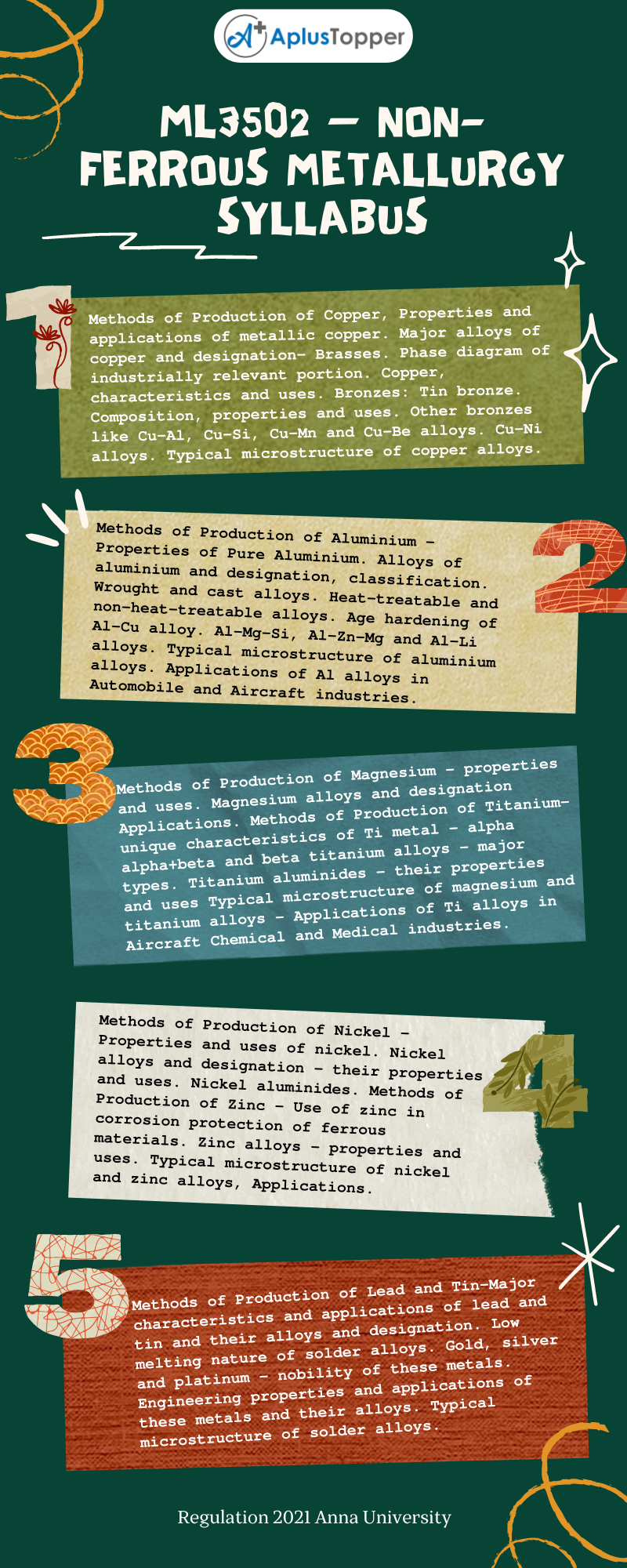

ML3502 – Non-Ferrous Metallurgy Syllabus

Unit – I: Copper And Copper Alloys

Methods of Production of Copper, Properties and applications of metallic copper. Major alloys of copper and designation- Brasses. Phase diagram of industrially relevant portion. Copper, characteristics and uses. Bronzes: Tin bronze. Composition, properties and uses. Other bronzes like Cu-Al, Cu-Si, Cu-Mn and Cu-Be alloys. Cu-Ni alloys. Typical microstructure of copper alloys.

Unit – II: Aluminium And Its Alloys

Methods of Production of Aluminium- Properties of Pure Aluminium. Alloys of aluminium and designation, classification. Wrought and cast alloys. Heat-treatable and non-heat-treatable alloys. Age hardening of Al-Cu alloy. Al-Mg-Si, Al-Zn-Mg and Al-Li alloys. Typical microstructure of aluminium alloys. Applications of Al alloys in Automobile and Aircraft industries.

Unit – III: Magnesium And Titanium Alloys

Methods of Production of Magnesium – properties and uses. Magnesium alloys and designation Applications. Methods of Production of Titanium- unique characteristics of Ti metal – alpha alpha+beta and beta titanium alloys – major types. Titanium aluminides – their properties and uses Typical microstructure of magnesium and titanium alloys – Applications of Ti alloys in Aircraft Chemical and Medical industries.

Unit – IV: Nickel And Zinc Alloys

Methods of Production of Nickel – Properties and uses of nickel. Nickel alloys and designation – their properties and uses. Nickel aluminides. Methods of Production of Zinc – Use of zinc in corrosion protection of ferrous materials. Zinc alloys – properties and uses. Typical microstructure of nickel and zinc alloys, Applications.

Unit – V: Lead, Tin And Precious Metals

Methods of Production of Lead and Tin-Major characteristics and applications of lead and tin and their alloys and designation. Low melting nature of solder alloys. Gold, silver and platinum – nobility of these metals. Engineering properties and applications of these metals and their alloys. Typical microstructure of solder alloys.

Text Books:

- K.G.Budinski and M.K.Budinski, ”Engineering Materials – Properties and Selection”, PHI Learning Pvt. Ltd., New Delhi, 2010.

- Sidney H. Avner, “Introduction to Physical Metallurgy”, Tata McGraw-Hill, 2nd Edition, 1997.

References:

- Ahindra Ghosh, Hem Shanker Ray, “Principles of Extractive Metallurgy”, New Age International, Reprint 2001.

- Balram Gupta, ”Aerospace Materials”, Vol. 1, 2 and 3, S. Chand and Co., New Delhi, 1996.

- Clark and Varney, ”Physical Metallurgy for Engineers”, Affiliated East West Press, New Delhi, 1987.

- W.H. Dennis, ”Metallurgy of the Nonferrous Metals”, Sir Isaac Pitman and Sons, London,1967.

- William F. Smith, ”Structure and Properties of Engineering Alloys”, McGraw Hill, USA, 1993.

Related Posts Of Semester – V:

Must Read: