Heat Treatment of Metals and Alloys is the subject of semester IV of Anna University B.E Material Science And Engineering Syllabus. In this article, we are glad to provide the syllabus of the heat treatment of metals and alloys part of Semester IV Subjects in the first-year course.

We intend to provide the subject code ML3404 – Heat Treatment of Metals and Alloys syllabus based on regulation 2021 by Anna University. You can get an idea of the topics in the syllabus of the heat treatment of metals and alloys. We hope that the absolute idea on the syllabus will assist the students in avoiding confusion of revision according to weightage. We also include required textbooks and references. If you require anything regarding the syllabus you can comment in the below section. Hope you like this information. Don’t forget to share.

If you want to know more about the syllabus of B.E. Material Science And Engineering connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.E. Material Science And Engineering Syllabus Regulation 2021 Anna University.

Aim Of Objectives:

The main learning objective of this course is to prepare students for:

- Having necessary background to design/select the necessary heat treatment for attaining the appropriate microstructure for the desired properties.

- Getting a comprehensive understanding of the various transformation reactions associated with the changes in microstructures and properties that occur due to controlled heat treatment.

- Understanding different case hardening techniques used in industries.

- Distinguishing the various Heat treatment furnaces, Quenching media and the heat treatment of some special alloys.

- Getting an insight on the heat treatments employed for special alloys.

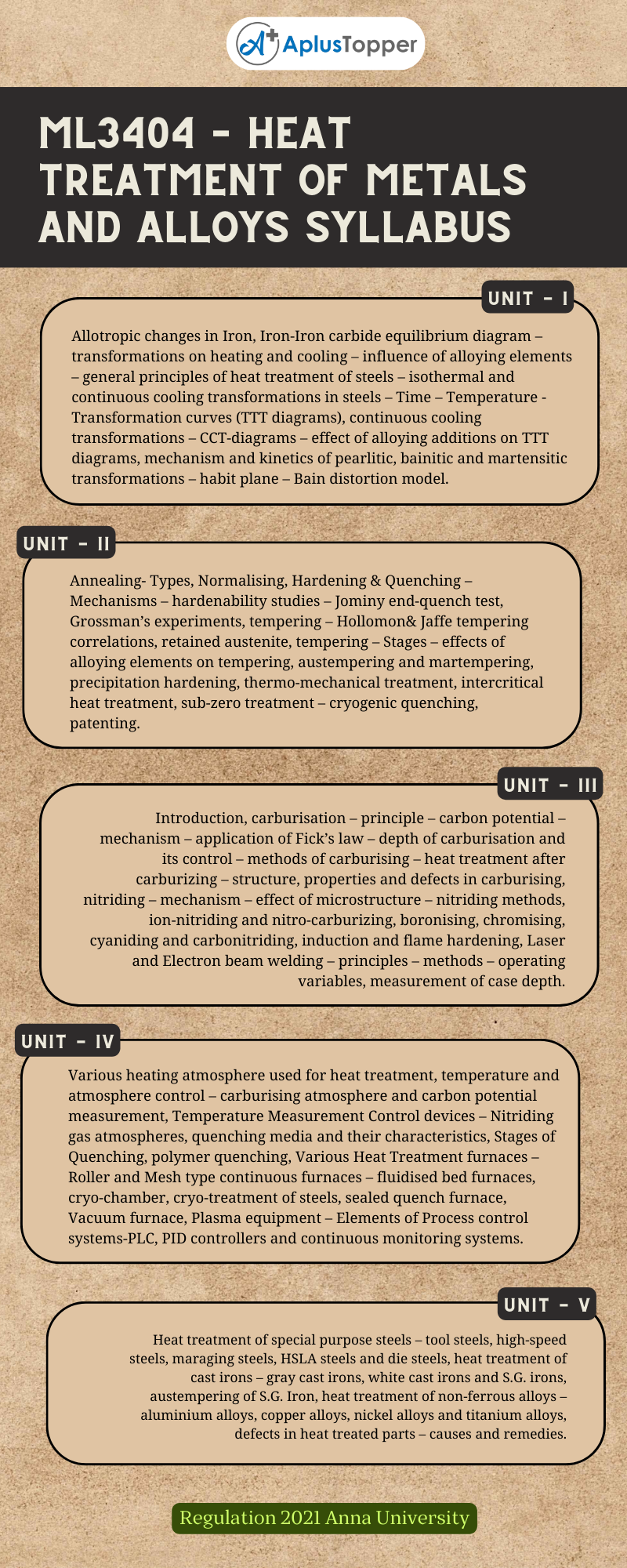

ML3404 – Heat Treatment of Metals and Alloys Syllabus

Unit – I: Transformations In Steels

Allotropic changes in Iron, Iron-Iron carbide equilibrium diagram – transformations on heating and cooling – influence of alloying elements – general principles of heat treatment of steels – isothermal and continuous cooling transformations in steels – Time – Temperature -Transformation curves (TTT diagrams), continuous cooling transformations – CCT-diagrams – effect of alloying additions on TTT diagrams, mechanism and kinetics of pearlitic, bainitic and martensitic transformations – habit plane – Bain distortion model.

Unit – II: Heat Treatment Processes

Annealing- Types, Normalising, Hardening & Quenching –Mechanisms – hardenability studies – Jominy end-quench test, Grossman’s experiments, tempering – Hollomon& Jaffe tempering correlations, retained austenite, tempering – Stages – effects of alloying elements on tempering, austempering and martempering, precipitation hardening, thermo-mechanical treatment, intercritical heat treatment, sub-zero treatment – cryogenic quenching, patenting.

Unit – III: Case Hardening

Introduction, carburisation – principle – carbon potential – mechanism – application of Fick’s law – depth of carburisation and its control – methods of carburising – heat treatment after carburizing – structure, properties and defects in carburising, nitriding – mechanism – effect of microstructure – nitriding methods, ion-nitriding and nitro-carburizing, boronising, chromising, cyaniding and carbonitriding, induction and flame hardening, Laser and Electron beam welding – principles – methods – operating variables, measurement of case depth.

Unit – IV: Furnaces, Atmosphere And Process Control

Various heating atmosphere used for heat treatment, temperature and atmosphere control – carburising atmosphere and carbon potential measurement, Temperature Measurement Control devices – Nitriding gas atmospheres, quenching media and their characteristics, Stages of Quenching, polymer quenching, Various Heat Treatment furnaces – Roller and Mesh type continuous furnaces – fluidised bed furnaces, cryo-chamber, cryo-treatment of steels, sealed quench furnace, Vacuum furnace, Plasma equipment – Elements of Process control systems-PLC, PID controllers and continuous monitoring systems.

Unit – V: Heat Treatment Of Specific Alloys

Heat treatment of special purpose steels – tool steels, high-speed steels, maraging steels, HSLA steels and die steels, heat treatment of cast irons – gray cast irons, white cast irons and S.G. irons, austempering of S.G. Iron, heat treatment of non-ferrous alloys – aluminium alloys, copper alloys, nickel alloys and titanium alloys, defects in heat treated parts – causes and remedies.

Text Books:

- Rajan, T. V., Sharma, C. P., Ashok Sharma., “Heat Treatment Principles and Techniques” Prentice-Hall of India Pvt. Ltd., New Delhi, 2011.

- Vijendra Singh, “Heat Treatment of Metals”, Second edition, Standard Publishers Distributors New Delhi, 2012.

References:

- ASM Handbook “Heat Treating”, Vol.4., ASM International, 1999.

- I. Novikov, “Theory of Heat Treatment of Metals”, MIR Publishers, Moscow, 1978.

- Prabhudev. K. H. “Handbook of Heat Treatment of Steels”, Tata McGraw-Hill, Publishing Co., New Delhi, 1988.

- Sydney H. Avner, “Introduction to Physical Metallurgy”, Tata McGraw Hill, New Delhi, 1997.

Related Posts Of Semester – IV:

- ML3401 – Characterisation of Materials

- ML3402 – Iron and Steel Making

- ML3403 – Mechanical Behaviour of Materials

- CE3391 – Fluid Mechanics and Machinery

- GE3451 – Environmental Sciences and Sustainability

Must Read: