This article code MF3502 explains the subject syllabus of Anna University B.E Manufacturing Engineering fifth semester. We aim to provide the geometric dimensioning and tolerancing syllabus based on regulation 2021.

We intend to give helpful information regarding the syllabus Of Anna University B.E Manufacturing Engineering students. Subject code MF3502 – Geometric Dimensioning and Tolerancing syllabus assists the students in getting unit-wise info without leaving a topic from the syllabus. We included the required textbooks and references. The following image we added in this article will help you just by reading you will be able to get the whole syllabus of this subject. Hope you find this information useful. Never forget to share with your friends if you like this information. Comment below if you have any doubts regarding the syllabus of the subject.

If you want to know more about the syllabus of B.E. Manufacturing Engineering connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.E. Manufacturing Engineering Syllabus Anna University Regulation 2021.

Aim Of Objectives:

The main learning objective of this course is to prepare students for:

- A variety of symbols are used on design drawings to replace words.

- Types of geometric controls and what they are used to control.

- What a datum and a datum feature are and why they are chosen.

- How to convert from plus and minus tolerancing to geometric tolerancing.

- How to measure MMC and LMC.

- How to apply geometric tolerances of flatness, perpendicularity and position in sequence.

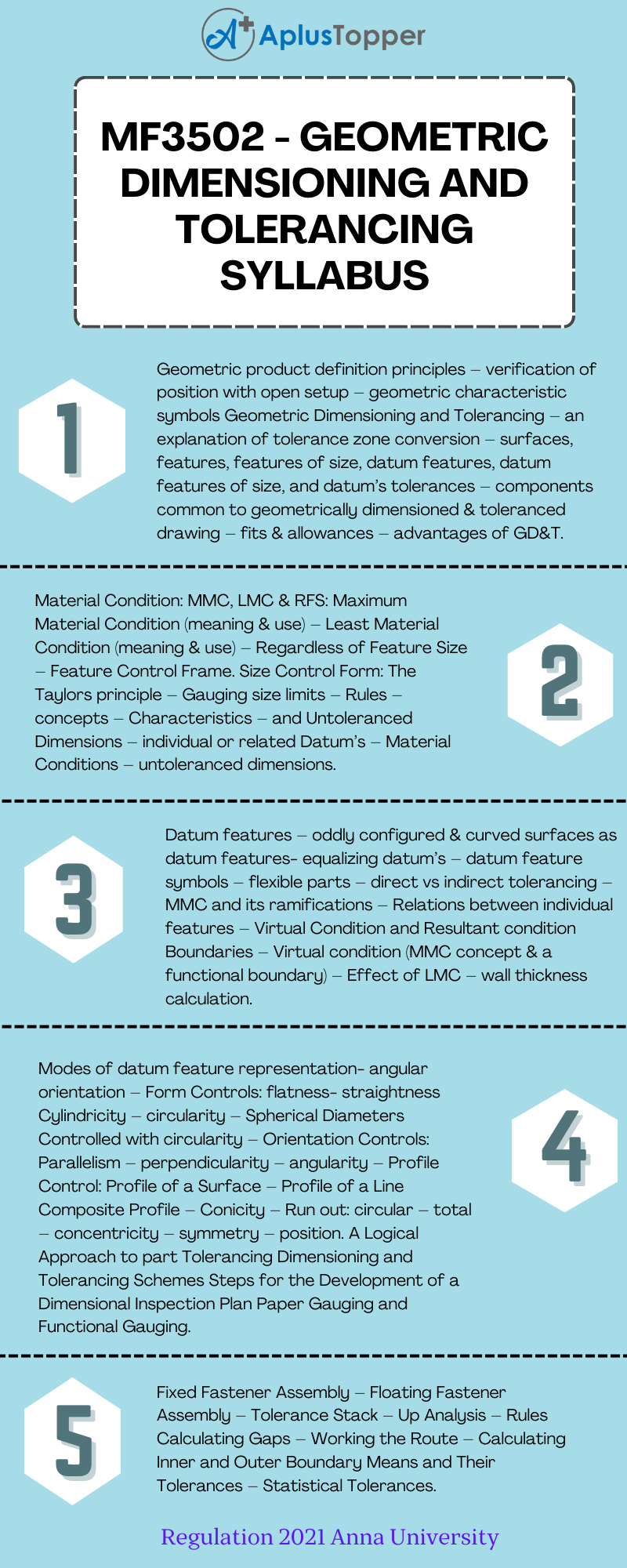

MF3502 – Geometric Dimensioning and Tolerancing Syllabus

Unit – I: Introduction

Geometric product definition principles – verification of position with open setup – geometric characteristic symbols Geometric Dimensioning and Tolerancing – an explanation of tolerance zone conversion – surfaces, features, features of size, datum features, datum features of size, and datum’s tolerances – components common to geometrically dimensioned & toleranced drawing – fits & allowances – advantages of GD&T.

Unit – II: Material Condition & Size Control Form

Material Condition: MMC, LMC & RFS: Maximum Material Condition (meaning & use) – Least Material Condition (meaning & use) – Regardless of Feature Size – Feature Control Frame. Size Control Form: The Taylors principle – Gauging size limits – Rules – concepts – Characteristics – and Untoleranced Dimensions – individual or related Datum’s – Material Conditions – untoleranced dimensions.

Unit – III: Datums

Datum features – oddly configured & curved surfaces as datum features- equalizing datum’s – datum feature symbols – flexible parts – direct vs indirect tolerancing – MMC and its ramifications – Relations between individual features – Virtual Condition and Resultant condition Boundaries – Virtual condition (MMC concept & a functional boundary) – Effect of LMC – wall thickness calculation.

Unit – IV: Datum Feature Of Size Representation

Modes of datum feature representation- angular orientation – Form Controls: flatness- straightness Cylindricity – circularity – Spherical Diameters Controlled with circularity – Orientation Controls: Parallelism – perpendicularity – angularity – Profile Control: Profile of a Surface – Profile of a Line Composite Profile – Conicity – Run out: circular – total – concentricity – symmetry – position. A Logical Approach to part Tolerancing Dimensioning and Tolerancing Schemes Steps for the Development of a Dimensional Inspection Plan Paper Gauging and Functional Gauging.

Unit – V: Tolerance Stack-Up Analysis

Fixed Fastener Assembly – Floating Fastener Assembly – Tolerance Stack – Up Analysis – Rules Calculating Gaps – Working the Route – Calculating Inner and Outer Boundary Means and Their Tolerances – Statistical Tolerances.

Text Books:

- James D. Meadows Geometric Dimensioning and Tolerancing – Applications, Analysis & Measurement [per ASME Y14.5-2009] James D. Meadows & Assoc inc, ISBN: 0- 9714401 -6-6.

- Bryan R. Fischer, Mechanical tolerance stack up and analysis, Marcel Dekker, 2004 – Technology & Engineering.

References:

- Robert G. Campbell, Edward S. Roth, “Integrated product design and Manufacturing using Geometric Dimensioning & Tolerancing” Marcel Dekker, Inc, New York.Basel,ISBN:0-8247-8890-7.

- G. Henzold, Geometrical dimensioning and tolerancing for design, manufacturing and inspection, Butterworth-Heinemann, 2006.

- Gene R. Cogorno, Geometric dimensioning and tolerancing for mechanical design, McGraw-Hll, 2006.

- James D Meadows, “Geometric Dimensioning and Tolerancing”, Marcel Dekker, Inc James D Meadows, “Measurement of Geometric Tolerances in Manufacturing” Marcel Dekker, Inc.

- P S Gill, “Geometric Dimensioning and Tolerancing”, S K Kataria & sons, 2005-6.

Related Posts On Semester – V:

Must Read: