This article code MF3501 explains the subject syllabus of Anna University B.E Manufacturing Engineering fifth semester. We aim to provide the basics of plastics engineering syllabus based on regulation 2021.

We intend to give helpful information regarding the syllabus Of Anna University B.E Manufacturing Engineering students. Subject code MF3501 – Basics of Plastics Engineering syllabus assists the students in getting unit-wise info without leaving a topic from the syllabus. We included the required textbooks and references. The following image we added in this article will help you just by reading you will be able to get the whole syllabus of this subject. Hope you find this information useful. Never forget to share with your friends if you like this information. Comment below if you have any doubts regarding the syllabus of the subject.

If you want to know more about the syllabus of B.E. Manufacturing Engineering connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.E. Manufacturing Engineering Syllabus Anna University Regulation 2021.

Aim Of Objectives:

- To learn about the various plastics materials.

- To study about the general properties, processing behavior and applications of different class of plastics materials.

- To understand the various processing techniques of plastic materials.

- To develop the knowledge of National & International standards for testing methods.

- To enable the students to identify and compare the properties of different plastics materials.

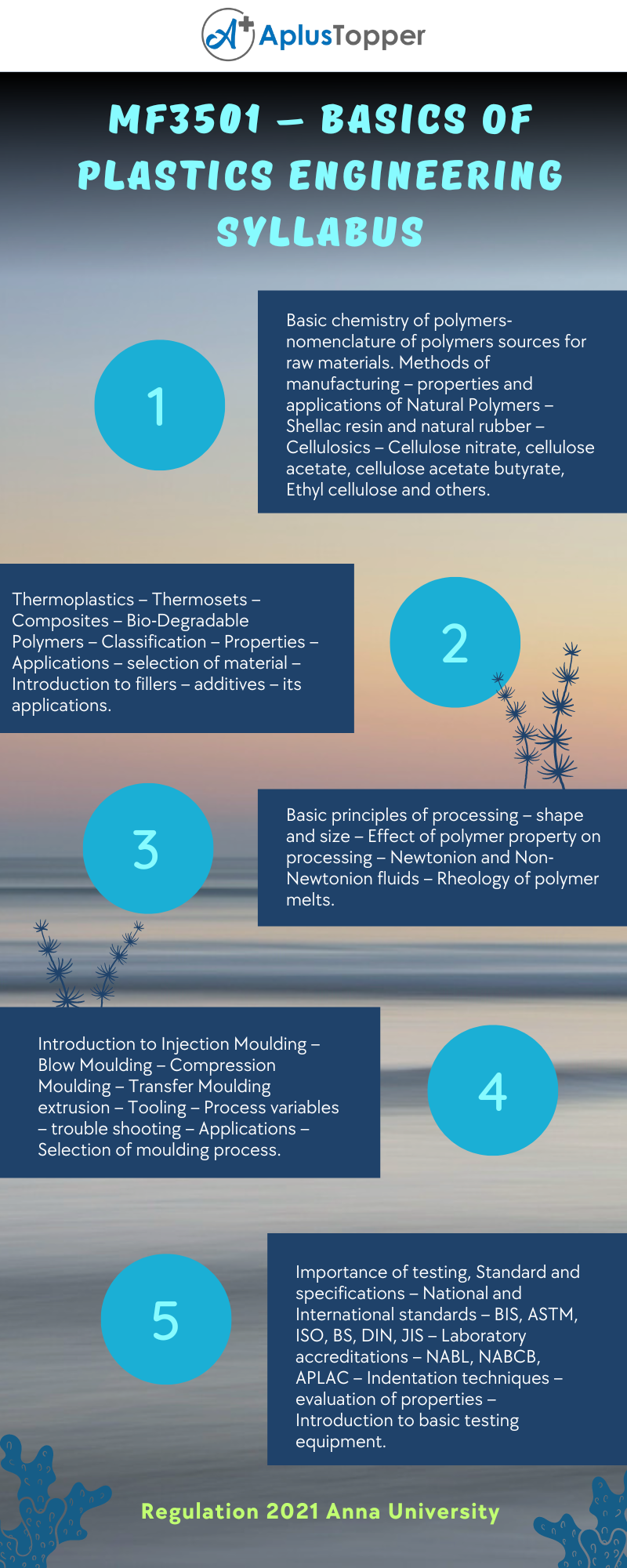

MF3501 – Basics of Plastics Engineering Syllabus

Unit – I: Plastic Materials

Basic chemistry of polymers-nomenclature of polymers sources for raw materials. Methods of manufacturing – properties and applications of Natural Polymers – Shellac resin and natural rubber – Cellulosics – Cellulose nitrate, cellulose acetate, cellulose acetate butyrate, Ethyl cellulose and others.

Unit – II: Types Of Plastic Materials

Thermoplastics – Thermosets – Composites – Bio-Degradable Polymers – Classification – Properties – Applications – selection of material – Introduction to fillers – additives – its applications.

Unit – III: Plastics Processing

Basic principles of processing – shape and size – Effect of polymer property on processing – Newtonion and Non-Newtonion fluids – Rheology of polymer melts.

Unit – IV: Processing Techniques

Introduction to Injection Moulding – Blow Moulding – Compression Moulding – Transfer Moulding extrusion – Tooling – Process variables – trouble shooting – Applications – Selection of moulding process.

Unit – V: Testing Of Plastics

Importance of testing, Standard and specifications – National and International standards – BIS, ASTM, ISO, BS, DIN, JIS – Laboratory accreditations – NABL, NABCB, APLAC – Indentation techniques – evaluation of properties – Introduction to basic testing equipment.

Text Books:

- J.A.Brydson, “Plastics Materials”, Butterworth- Heinemann – Oxford, 7th Ed., 2001.

- Allen; W. S. and Baker; P. N., Hand Book of Plastic Technology, Volume-1 & 2, CBS Publishers and Distributors, New Delhi (2009).

References:

- Irvin. I. Rubin, “Handbook of Plastic Materials and Technology”, Wiley Interscience, NY, 1990.

- Guide to Injection Molding of Plastics By Bolur, P.C.,

- Brown; Paul F (Ed), Handbook of Plastics Test Methods, Longman Scientific and Technical, Harlow (1988).

- J.S. Anand, K. Ramamurthy, K. Palanivelu& C. Brahatheeswaran, How to Identify Plastics by Simple Methods, 1997.

- Vishu Shah, Handbook of Plastics Testing Technology, John Wiley & Sons. Inc.New York, 1998.

Related Posts On Semester – V:

Must Read: