Code – ME8451, this article about B.E/B.Tech./B.Arch Mechanical Engineering Semester IV Manufacturing Technology-II. Students are requested to make notes or PDFs of the semester in Manufacturing Technology-II for effective preparation from here. It will help you to understand what are the topics in the syllabus of Manufacturing Technology-II.

And to make preparation strategies to score well in the examinations. Unit-wise detailed syllabus is given below in one place, in the following article ME8451 – Manufacturing Technology-II. If the information helps you, kindly share it with your classmates.

If you want to know more about the syllabus of B.E Mechanical Engineering connected to an affiliated institution’s four-year undergraduate degree programme. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.E Mechanical Engineering Syllabus Anna University Regulation 2017.

Aim Of Concept:

- To understand the concept and basic mechanics of metal cutting, working of standard machine tools such as lathe, shaping and allied machines, milling, drilling and allied machines, grinding and allied machines and broaching.

- To understand the basic concepts of Computer Numerical Control (CNC) of machine tools and CNC Programming.

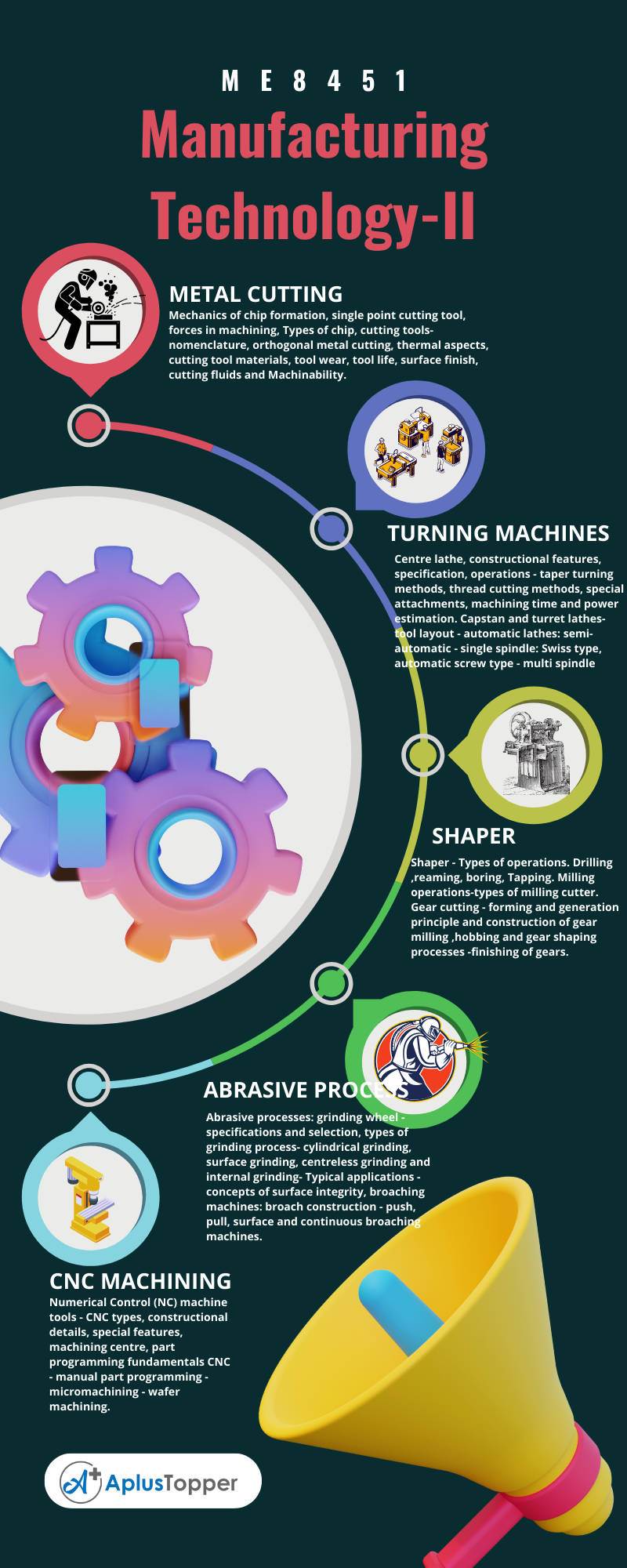

ME8451 – Manufacturing Technology-II Syllabus

Unit I: Theory Of Metal Cutting

Mechanics of chip formation, single point cutting tool, forces in machining, Types of chip, cutting tools- nomenclature, orthogonal metal cutting, thermal aspects, cutting tool materials, tool wear, tool life, surface finish, cutting fluids and Machinability.

Unit II: Turning Machines

Centre lathe, constructional features, specification, operations – taper turning methods, thread cutting methods, special attachments, machining time and power estimation. Capstan and turret lathes- tool layout – automatic lathes: semi-automatic – single spindle: Swiss type, automatic screw type – multi spindle

Unit III: Shaper, Milling And Gear Cutting Machines

Shaper – Types of operations. Drilling ,reaming, boring, Tapping. Milling operations-types of milling cutter. Gear cutting – forming and generation principle and construction of gear milling ,hobbing and gear shaping processes -finishing of gears.

Unit IV: Abrasive Process And Broaching

Abrasive processes: grinding wheel – specifications and selection, types of grinding process- cylindrical grinding, surface grinding, centreless grinding and internal grinding- Typical applications – concepts of surface integrity, broaching machines: broach construction – push, pull, surface and continuous broaching machines.

Unit V: Cnc Machining

Numerical Control (NC) machine tools – CNC types, constructional details, special features, machining centre, part programming fundamentals CNC – manual part programming – micromachining – wafer machining.

Text Books:

- Hajra Choudhury, “Elements of Workshop Technology”, Vol.II., Media Promoters 2014

- Rao. P.N “Manufacturing Technology – Metal Cutting and Machine Tools”, 3rd Edition, Tata McGraw-Hill, New Delhi, 2013.

References:

- Richerd R Kibbe, John E. Neely, Roland O. Merges and Warren J.White “Machine Tool Practices”, Prentice Hall of India, 1998.

- Geofrey Boothroyd, “Fundamentals of Metal Machining and Machine Tools”, Mc Graw Hill, 1984.

- HMT, “Production Technology”, Tata McGraw Hill, 1998.

- Roy. A.Lindberg, “Process and Materials of Manufacture,” Fourth Edition, PHI/Pearson Education 2006.

If you want to check the syllabus of other branches provided by Anna University, Anna University syllabus Regulation 2017 will assist you in a clear path. Hope you find the required details.

Related Posts Of Semester – IV:

- MA8452 – Statistics and Numerical Methods Syllabus

- ME8492 – Kinematics of Machinery Syllabus

- ME8491 – Engineering Metallurgy Syllabus

- CE8395 – Strength of Materials for Mechanical Engineers Syllabus

- ME8493 – Thermal Engineering-1 Syllabus

- ME8462 – Manufacturing Technology Laboratory -11 Syllabus

- CE8381 – Strength of Materials and Fluid Mechanics and Machinery Laboratory Syllabus

- HS8461 – Advanced Reading and Writing Syllabus