Code – ME8351, this article about B.E/B.Tech./B.Arch Mechanical Engineering Semester III Manufacturing Technology-I syllabus. Students are requested to make notes or PDFs of the semester in Manufacturing Technology-I for effective preparation from here. It will help you to understand what are the topics in the syllabus of Manufacturing Technology-I.

And to make preparation strategies to score well in the examinations. Unit-wise detailed syllabus is given below in one place, in the following article ME8351 – Manufacturing Technology-I. If the information helps you, kindly share it with your classmates.

If you want to know more about the syllabus of B.E Mechanical Engineering connected to an affiliated institution’s four-year undergraduate degree programme. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.E Mechanical Engineering Syllabus Anna University Regulation 2017.

Aim Of Concept:

To introduce the concepts of basic manufacturing processes and fabrication techniques, such as metal casting, metal joining, metal forming and manufacture of plastic components.

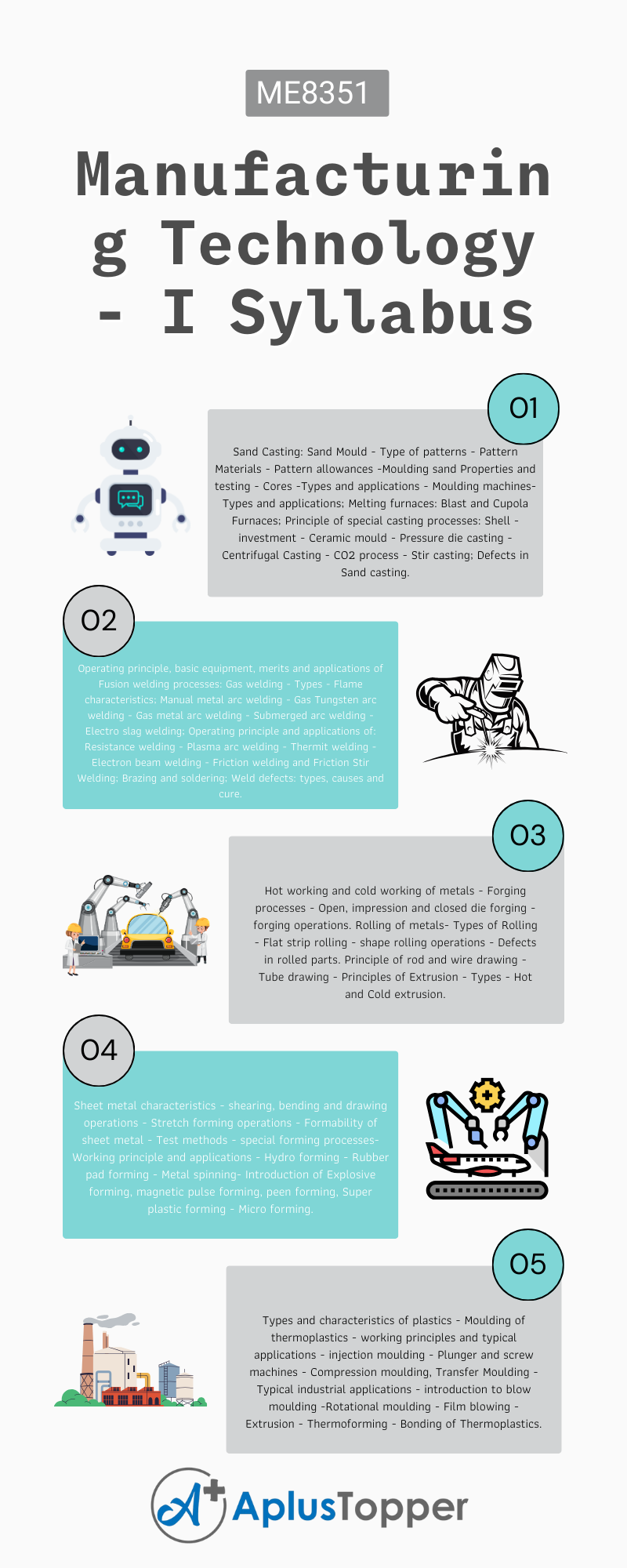

ME8351 – Manufacturing Technology-I Syllabus Regulation 2017

Unit I: Metal Casting Processes

Sand Casting: Sand Mould – Type of patterns – Pattern Materials – Pattern allowances -Moulding sand Properties and testing – Cores -Types and applications – Moulding machines- Types and applications; Melting furnaces: Blast and Cupola Furnaces; Principle of special casting processes: Shell – investment – Ceramic mould – Pressure die casting – Centrifugal Casting – CO2 process – Stir casting; Defects in Sand casting.

Unit II: Joining Processes

Operating principle, basic equipment, merits and applications of Fusion welding processes: Gas welding – Types – Flame characteristics; Manual metal arc welding – Gas Tungsten arc welding – Gas metal arc welding – Submerged arc welding – Electro slag welding; Operating principle and applications of: Resistance welding – Plasma arc welding – Thermit welding – Electron beam welding – Friction welding and Friction Stir Welding; Brazing and soldering; Weld defects: types, causes and cure.

Unit III: Metal Forming Processes

Hot working and cold working of metals – Forging processes – Open, impression and closed die forging – forging operations. Rolling of metals- Types of Rolling – Flat strip rolling – shape rolling operations – Defects in rolled parts. Principle of rod and wire drawing – Tube drawing – Principles of Extrusion – Types – Hot and Cold extrusion.

Unit IV: Sheet Metal Processes

Sheet metal characteristics – shearing, bending and drawing operations – Stretch forming operations – Formability of sheet metal – Test methods – special forming processes-Working principle and applications – Hydro forming – Rubber pad forming – Metal spinning- Introduction of Explosive forming, magnetic pulse forming, peen forming, Super plastic forming – Micro forming.

Unit V: Manufacture Of Plastic Components

Types and characteristics of plastics – Moulding of thermoplastics – working principles and typical applications – injection moulding – Plunger and screw machines – Compression moulding, Transfer Moulding – Typical industrial applications – introduction to blow moulding -Rotational moulding – Film blowing – Extrusion – Thermoforming – Bonding of Thermoplastics.

Text Books:

- Hajra Choudhary S.K and Hajra Choudhury. AK., “Elements of workshop Technology”, volume I and II, Media promoters and Publishers Private Limited, Mumbai, 2008

- Kalpakjian. S, “Manufacturing Engineering and Technology”, Pearson Education India Edition, 2013.

References:

- Gowri P. Hariharan, A.Suresh Babu, “Manufacturing Technology I”, Pearson Education, 2008

- Paul Degarma E, Black J.T and Ronald A. Kosher, “Materials and Processes, in Manufacturing” Eight Edition, Prentice – Hall of India, 1997.

- Rao, P.N. “Manufacturing Technology Foundry, Forming and Welding”, 4th Edition, TMH-2013

- Roy. A. Lindberg, “Processes and Materials of Manufacture”, PHI / Pearson Education, 2006

- Sharma, P.C., “A Text book of Production Technology”, S.Chand and Co. Ltd., 2014.

If you want to check the syllabus of other branches provided by Anna University, Anna University syllabus Regulation 2017 will assist you in a clear path. Hope you find the required details.

Related Posts Of Semester – III:

- MA8353 – Transforms and Partial Differential Equations Syllabus

- ME8391 – Engineering Thermodynamics Syllabus

- CE8394 – Fluid Mechanics and Machinery Syllabus

- EE8353 – Electrical Drives and Controls Syllabus

- ME8361 – Manufacturing Technology Laboratory -1 Syllabus

- ME8381 – Computer Aided Machine Drawing Syllabus

- EE8361 – Electrical Engineering Laboratory Syllabus

- HS8381 – Interpersonal Skills/Listening & Speaking Syllabus