Regulation 2021 Anna University Code – ME3392 deals with the semester – III Engineering Materials and Metallurgy Syllabus of B.E Mechanical Engineering. Most of the semester syllabus tries to give both practical and theoretical knowledge to the students. To acquire the proper knowledge regarding the studies to prepare for the examination, need a detailed syllabus right?

This article will assist you in gaining most of the syllabus details. We tried our best to provide the required syllabus info. Chapter-wise syllabus along with reference books written by experts and textbooks added. Hence in this article ME3392 – Engineering Materials and Metallurgy syllabus, we include all the details regarding the examination. Students can easily get all the data regarding the syllabus on one page. Hope you will understand the syllabus. And All the best for your exams. Don’t forget to share it with your friends.

If you want to know more about the syllabus of B.E Mechanical Engineering connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.E Mechanical Engineering Syllabus Anna University Regulation 2021.

Aim Of Objectives:

- To learn the constructing the phase diagram and using of iron-iron carbide phase diagram for microstructure formation.

- To learn selecting and applying various heat treatment processes and its microstructure formation.

- To illustrate the different types of ferrous and non-ferrous alloys and their uses in engineering field.

- To illustrate the different polymer, ceramics and composites and their uses in engineering field.

- To learn the various testing procedures and failure mechanisms in engineering field.

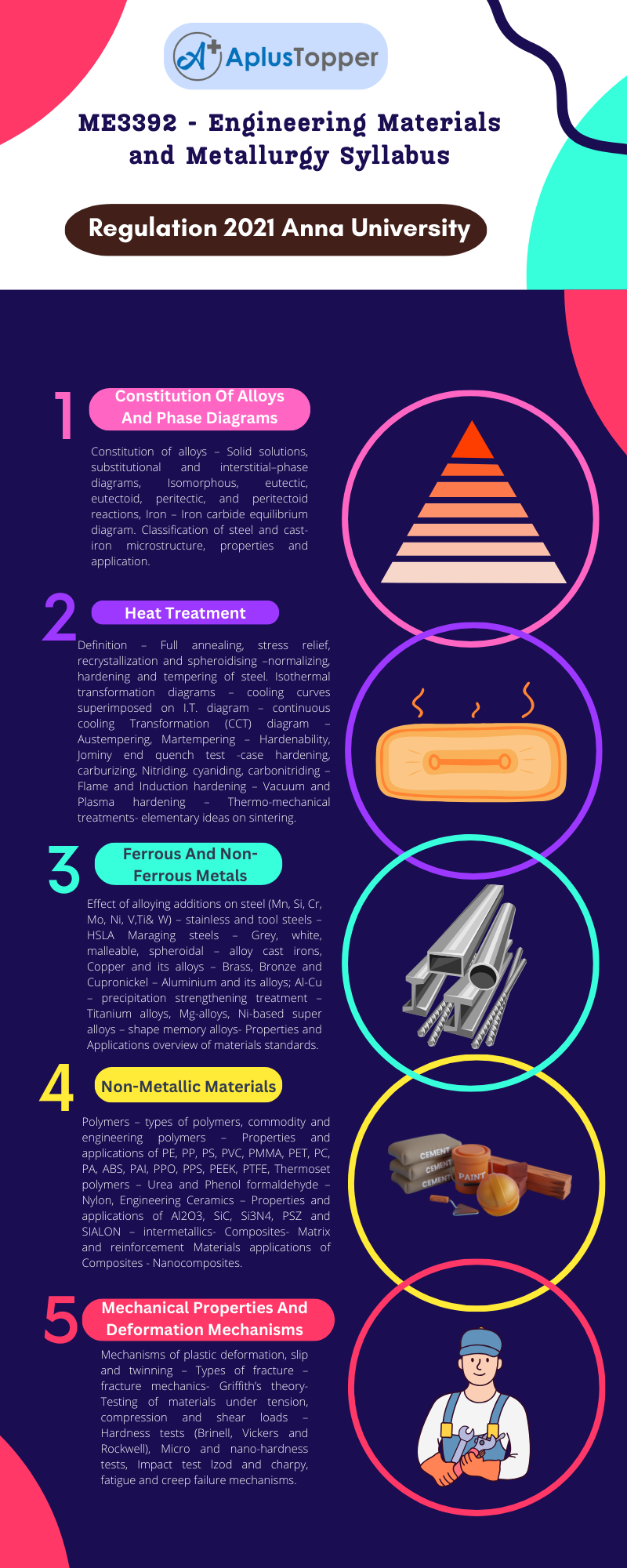

ME3392 – Engineering Materials and Metallurgy Syllabus

Unit I: Constitution Of Alloys And Phase Diagrams

Constitution of alloys – Solid solutions, substitutional and interstitial–phase diagrams, Isomorphous, eutectic, eutectoid, peritectic, and peritectoid reactions, Iron – Iron carbide equilibrium diagram. Classification of steel and cast-iron microstructure, properties and application.

Unit II: Heat Treatment

Definition – Full annealing, stress relief, recrystallization and spheroidising –normalizing, hardening and tempering of steel. Isothermal transformation diagrams – cooling curves superimposed on I.T. diagram – continuous cooling Transformation (CCT) diagram – Austempering, Martempering – Hardenability, Jominy end quench test -case hardening, carburizing, Nitriding, cyaniding, carbonitriding – Flame and Induction hardening – Vacuum and Plasma hardening – Thermo-mechanical treatments- elementary ideas on sintering.

Unit III: Ferrous And Non-Ferrous Metals

Effect of alloying additions on steel (Mn, Si, Cr, Mo, Ni, V,Ti& W) – stainless and tool steels – HSLA Maraging steels – Grey, white, malleable, spheroidal – alloy cast irons, Copper and its alloys – Brass, Bronze and Cupronickel – Aluminium and its alloys; Al-Cu – precipitation strengthening treatment – Titanium alloys, Mg-alloys, Ni-based super alloys – shape memory alloys- Properties and Applications overview of materials standards.

Unit IV: Non-Metallic Materials

Polymers – types of polymers, commodity and engineering polymers – Properties and applications of PE, PP, PS, PVC, PMMA, PET, PC, PA, ABS, PAI, PPO, PPS, PEEK, PTFE, Thermoset polymers – Urea and Phenol formaldehyde –Nylon, Engineering Ceramics – Properties and applications of Al2O3, SiC, Si3N4, PSZ and SIALON – intermetallics- Composites- Matrix and reinforcement Materials applications of Composites – Nanocomposites.

Unit V: Mechanical Properties And Deformation Mechanisms

Mechanisms of plastic deformation, slip and twinning – Types of fracture – fracture mechanics- Griffith’s theory- Testing of materials under tension, compression and shear loads – Hardness tests (Brinell, Vickers and Rockwell), Micro and nano-hardness tests, Impact test lzod and charpy, fatigue and creep failure mechanisms.

Text Books:

- Kenneth G.Budinski and Michael K. Budinski, “Engineering Materials”, Prentice Hall of India Private Limited, 9th edition,2018.

- Sydney H. Avner, “Introduction to Physical Metallurgy”, McGraw Hill Book Company, 1994.

References:

- A. Alavudeen, N. Venkateshwaran, and J. T. WinowlinJappes, A Textbook of Engineering Materials and Metallurgy, Laxmi Publications, 2006.

- Amandeep Singh Wadhwa, andHarvinder Singh Dhaliwal, A Textbook of Engineering Material and Metallurgy, University Sciences Press, 2008.

- G.S. Upadhyay and Anish Upadhyay, “Materials Science and Engineering”, Viva Books Pvt.Ltd, New Delhi, 2020.

- Raghavan.V, “Materials Science and Engineering”, Prentice Hall of India Pvt. Ltd. 6th edition, 2019.

- Williams D Callister, “Material Science and Engineering” Wiley India Pvt Ltd, 2nd edition Reprint 2019.

Related Posts on Semester – III:

- MA3351 – Transforms and Partial Differential Equations

- ME3351 – Engineering Mechanics

- ME3391 – Engineering Thermodynamics

- CE3391 – Fluid Mechanics and Machinery