FD3301 Subject code belongs to the Anna University, B.Tech Food Technology Semester III syllabus. In this article, we discuss the syllabus of the Fluid Mechanics and Mechanical Operations subject. We hope it helps the students prepare for the academic exams.

The following article, FD3301 – Fluid Mechanics and Mechanical Operations Syllabus assists the students in thorough preparation for theory examinations. We include the detailed syllabus along with the expertise referred textbooks and references. Students can easily get information regarding the Fluid Mechanics and Mechanical Operations syllabus, we add every concept to each unit. You can follow the information and prepare well if you have any doubts regarding the syllabus of this subject. You can comment below. Aplustopper.com will be available as soon as possible. Hope this information is useful. Don’t forget to share this information with your classmates.

If you want to know more about the syllabus of B.Tech Biotechnology and Biochemical Engineering Syllabus connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.Tech Food Technology Syllabus Anna University, Regulation 2021.

Aim Of Objectives:

To enable the students to understand the

- The mechanics of fluids through a thorough understanding of the properties of the fluids, behaviour of fluids under static conditions.

- Dynamics of fluids is introduced through the control volume approach which gives an integrated understanding of the transport of mass, momentum and energy.

- Applications of the conservation laws to a) flow measurements b) flow through pipes (both laminar and turbulent) and c) forces on vanes.

- Mechanical and Contact equilibrium separation processes of the components and their series of unit operations.

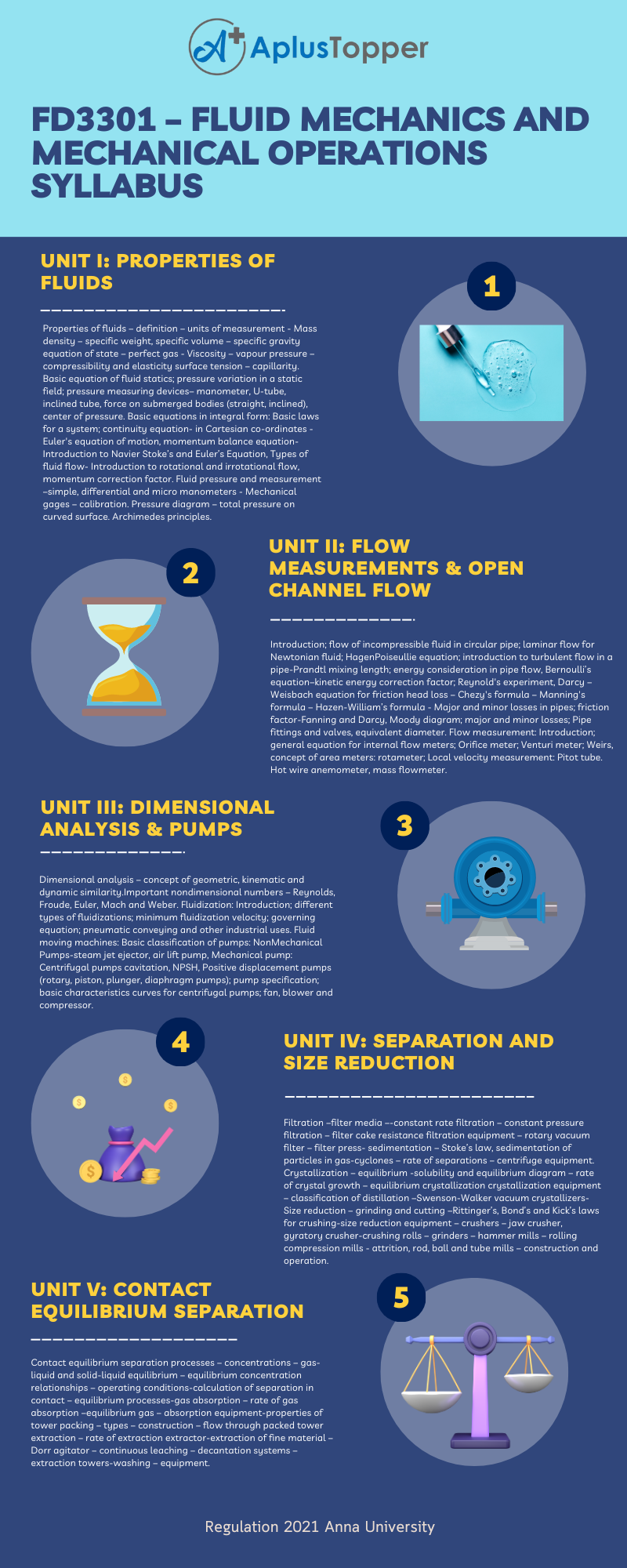

FD3301 – Fluid Mechanics and Mechanical Operations Syllabus

Unit I: Properties Of Fluids

Properties of fluids – definition – units of measurement – Mass density – specific weight, specific volume – specific gravity equation of state – perfect gas – Viscosity – vapour pressure – compressibility and elasticity surface tension – capillarity. Basic equation of fluid statics; pressure

variation in a static field; pressure measuring devices– manometer, U-tube, inclined tube, force on submerged bodies (straight, inclined), center of pressure. Basic equations in integral form: Basic laws for a system; continuity equation- in Cartesian co-ordinates – Euler’s equation of motion, momentum balance equation-Introduction to Navier Stoke’s and Euler’s Equation, Types of fluid flow- Introduction to rotational and irrotational flow, momentum correction factor. Fluid pressure and measurement –simple, differential and micro manometers – Mechanical gages – calibration.

Pressure diagram – total pressure on curved surface. Archimedes principles.

Unit II: Flow Measurements & Open Channel Flow

Introduction; flow of incompressible fluid in circular pipe; laminar flow for Newtonian fluid; HagenPoiseullie equation; introduction to turbulent flow in a pipe-Prandtl mixing length; energy consideration in pipe flow, Bernoulli’s equation–kinetic energy correction factor; Reynold’s experiment, Darcy – Weisbach equation for friction head loss – Chezy’s formula – Manning’s formula – Hazen-William’s formula – Major and minor losses in pipes; friction factor-Fanning and Darcy, Moody diagram; major and minor losses; Pipe fittings and valves, equivalent diameter. Flow measurement: Introduction; general equation for internal flow meters; Orifice meter; Venturi meter; Weirs, concept of area meters: rotameter; Local velocity measurement: Pitot tube. Hot wire anemometer, mass flowmeter.

Unit III: Dimensional Analysis & Pumps

Dimensional analysis – concept of geometric, kinematic and dynamic similarity.Important nondimensional numbers – Reynolds, Froude, Euler, Mach and Weber. Fluidization: Introduction; different types of fluidizations; minimum fluidization velocity; governing equation; pneumatic conveying and other industrial uses. Fluid moving machines: Basic classification of pumps: NonMechanical Pumps-steam jet ejector, air lift pump, Mechanical pump: Centrifugal pumps cavitation, NPSH, Positive displacement pumps (rotary, piston, plunger, diaphragm pumps); pump

specification; basic characteristics curves for centrifugal pumps; fan, blower and compressor.

Unit IV: Separation And Size Reduction

Filtration –filter media –-constant rate filtration – constant pressure filtration – filter cake resistance filtration equipment – rotary vacuum filter – filter press- sedimentation – Stoke’s law, sedimentation of particles in gas-cyclones – rate of separations – centrifuge equipment. Crystallization –

equilibrium -solubility and equilibrium diagram – rate of crystal growth – equilibrium crystallization crystallization equipment – classification of distillation –Swenson-Walker vacuum crystallizers- Size reduction – grinding and cutting –Rittinger’s, Bond’s and Kick’s laws for crushing-size reduction equipment – crushers – jaw crusher, gyratory crusher-crushing rolls – grinders – hammer mills – rolling compression mills – attrition, rod, ball and tube mills – construction and operation.

Unit V: Contact Equilibrium Separation

Contact equilibrium separation processes – concentrations – gas-liquid and solid-liquid equilibrium – equilibrium concentration relationships – operating conditions-calculation of separation in contact – equilibrium processes-gas absorption – rate of gas absorption –equilibrium gas – absorption equipment-properties of tower packing – types – construction – flow through packed tower extraction – rate of extraction extractor-extraction of fine material – Dorr agitator – continuous leaching – decantation systems – extraction towers-washing – equipment.

Text Books:

- Modi, P.N. and Seth S.M. “Hydraulics and fluid mechanics”. Standard Publishers Distributors, New Delhi,2010.

- Streeter, V.L. Wylie, E. B. and Bedford K.W, Fluid Mechanics. (9th ed) Tata McGraw Hill, New Delhi, 1998.

- Geankoplis, C.J. “Transport Processes and Separation Process Principles”, 4th Edition, Prentice Hall, 2003.

- McCabe W.L., Smith J.C. “Unit Operations in Chemical Engineering”, 7th Edition, McGraw – Hill Int., 2001.

- Earle, R.L. 2003. Unit Operations in Food Processing. Pergamon Press. Oxford. U.K.

- Geankoplis C.J.1999. Transport Process and Unit Operations. Prentice-Hall of India Private Limited, New Delhi.

References:

- Bansal, R.K., “A text book of fluid mechanics and hydraulic machinery”, Laxmi publications (P) Ltd., New Delhi, 2002.

- Grade, RJ.,.“Fluid mechanics through problems”. Wiley eastern Ltd., Madras,2002.

- Jain A. K. “Fluid Mechanics”. Khanna Publishers 1995.

Related Posts On Semester – III:

Must Read: