Design for Manufacturing is from Anna University conducting B.E Mechanical Engineering Sandwich containing semester V examination subject. In this article, we are glad to provide the syllabus of the Design for manufacturing.

We aim to provide the unit-wise syllabus for the students to get help with their preparation for the examination. With the assistance of the syllabus, you can able to learn before everyone else. You will get a good grip on the syllabus to make your preparation strategies. We also add appropriate textbooks and references from the expert faculty regarding the subject code CME391 – Design for Manufacturing Syllabus. Hope this information is useful. Kindly share it with your classmates if you like it.

If you want to know more about the B.E Mechanical Engineering Sandwich syllabus connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.E Mechanical Engineering Sandwich Syllabus Regulation 2021 Anna University.

Aim Of Objectives:

- To introduce economic process selection principles and general design principles for manufacturability in the development and design of products for various engineering applications.

- Also, apply design consideration principles of casting in the design of cast products.

- To learn design consideration principles of forming in the design of extruded, stamped, and forged products.

- To learn design consideration principles of machining in the design of turned, drilled, milled, planed, shaped, slotted, and ground products.

- To learn design consideration principles of welding in the design of welded products.

- To learn design consideration principles of assembly in the design of assembled products.

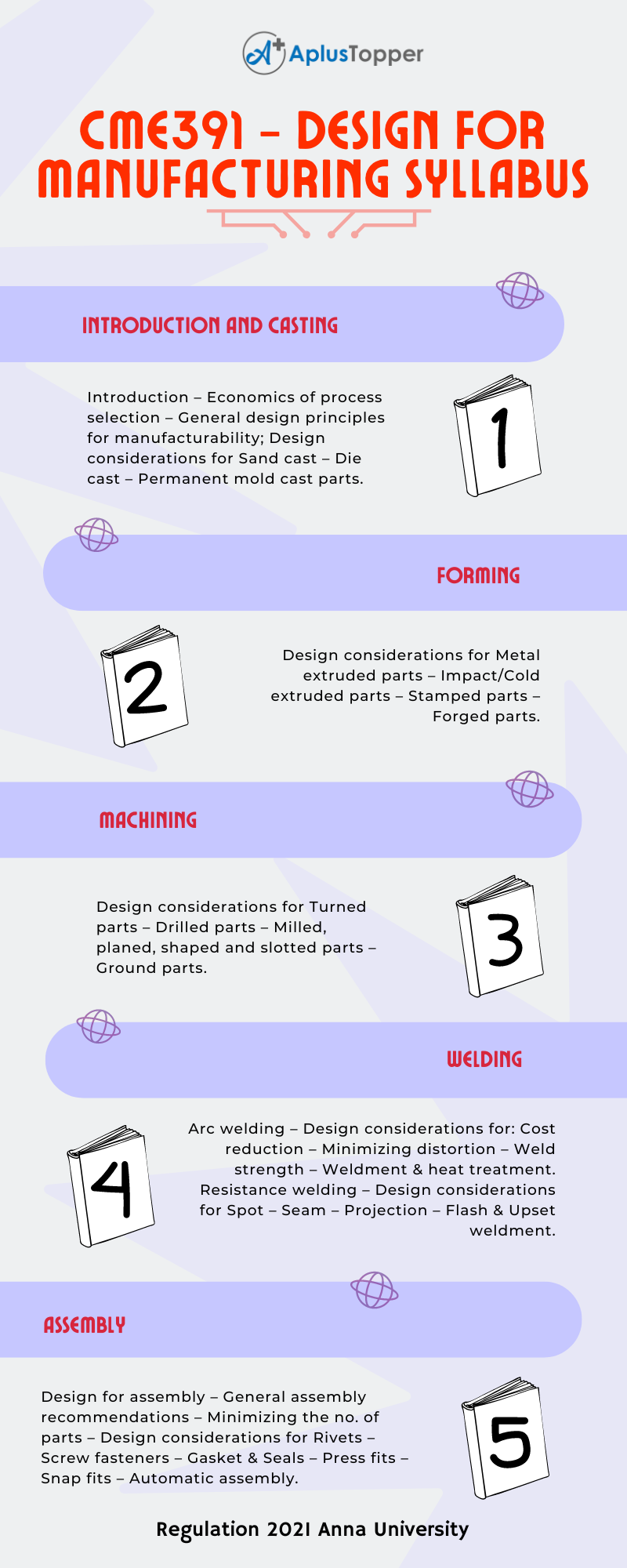

CME391 – Design for Manufacturing Syllabus

Unit – I: Introduction And Casting

Introduction – Economics of process selection – General design principles for manufacturability; Design considerations for Sand cast – Die cast – Permanent mold cast parts.

Unit – II: Forming

Design considerations for Metal extruded parts – Impact/Cold extruded parts – Stamped parts –Forged parts.

Unit – III: Machining

Design considerations for Turned parts – Drilled parts – Milled, planed, shaped and slotted parts – Ground parts.

Unit – IV: Welding

Arc welding – Design considerations for: Cost reduction – Minimizing distortion – Weld strength – Weldment & heat treatment. Resistance welding – Design considerations for Spot – Seam – Projection – Flash & Upset weldment.

Unit – V: Assembly

Design for assembly – General assembly recommendations – Minimizing the no. of parts – Design considerations for Rivets – Screw fasteners – Gasket & Seals – Press fits – Snap fits – Automatic assembly.

Text Books:

- James G. Bralla, “Handbook of Product Design for Manufacture”, McGraw Hill, 1986.

- O. Molloy, E.A. Warman, S. Tilley, Design for Manufacturing and Assembly: Concepts, Architectures and Implementation, Springer, 1998.

References:

- CorradoPoli, Design for Manufacturing: A Structured Approach, Elsevier, 2001.

- David M. Anderson, Design for Manufacturability & Concurrent Engineering: How to Design for Low Cost, Design in High Quality, Design for Lean Manufacture, and Design Quickly for Fast Production, CIM Press, 2004.

- Erik Tempelman, Hugh Shercliff, Bruno Ninaber van Eyben, Manufacturing and Design: Understanding the Principles of How Things Are Made, Elsevier, 2014.

- Henry Peck, “Designing for Manufacture”, Sir Isaac Pitman & Sons Ltd., 1973.

- Matousek, “Engineering Design”, Blackie & Sons, 1956.

Related Posts On Semester – V:

Must Read: