Regulation 2021 Anna University Code – CH3551 deals with the semester – V Mass Transfer II Laboratory Syllabus of B.TechChemical Engineering. Most of the semester syllabus tries to give both practical and theoretical knowledge to the students. To acquire the proper knowledge regarding the studies to prepare for the examination, need a detailed syllabus right?

This article will assist you in gaining most of the syllabus details. We tried our best to provide the required syllabus info. Chapter-wise syllabus along with reference books written by experts and textbooks added. Hence in this article CH3551 – Mass Transfer II syllabus, we include all the details regarding the examination. Students can easily get all the data regarding the syllabus on one page. Hope you will understand the syllabus. And All the best for your exams. Don’t forget to share it with your friends.

If you want to know more about the syllabus of B.Tech Chemical Engineering connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.Tech Chemical Engineering Syllabus Anna University Regulation 2021.

Aim Of Objective:

The course is aimed to-

Impart knowledge on how certain substances change composition, change in phases and exhibit their properties according to the changed environment. Also, to design absorber and stripper, distillation column, extraction and leaching equipment and adsorber.

CH3551 – Mass Transfer II Syllabus

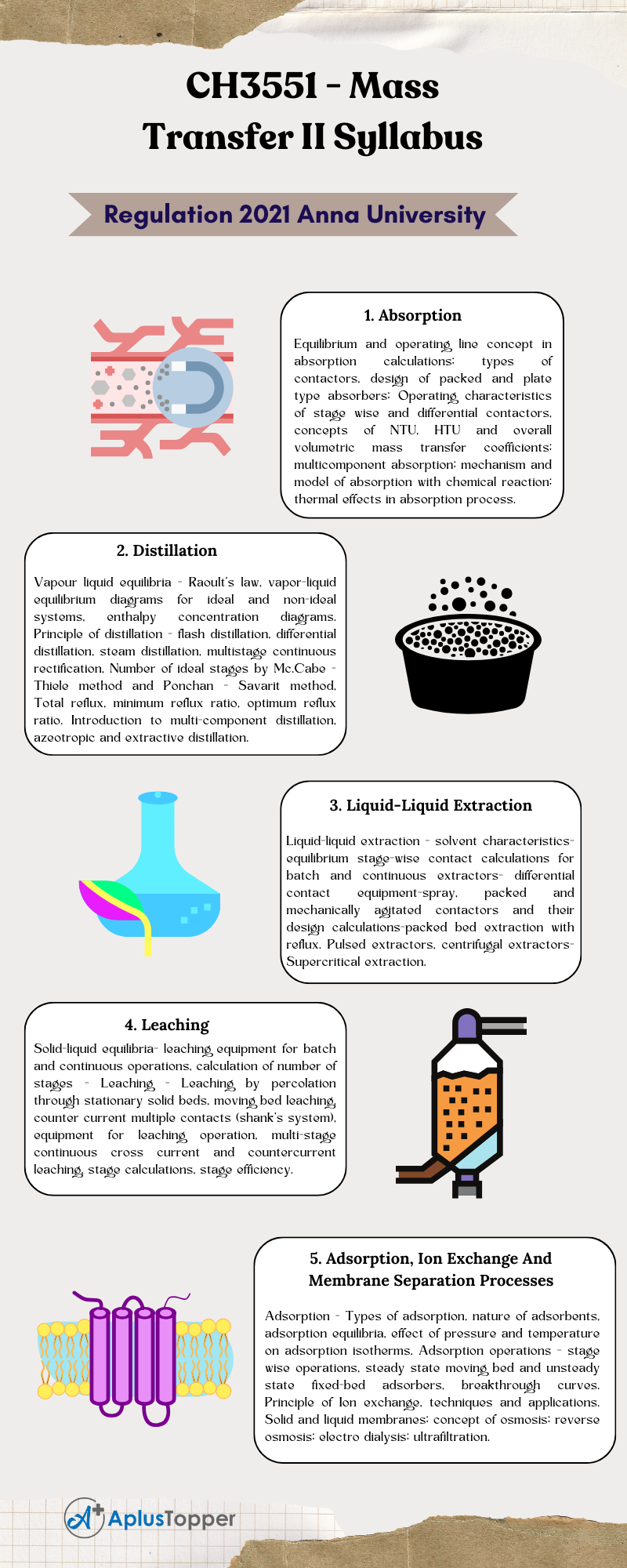

Unit I: Absorption

Equilibrium and operating line concept in absorption calculations; types of contactors, design of packed and plate type absorbers; Operating characteristics of stage wise and differential contactors, concepts of NTU, HTU and overall volumetric mass transfer coefficients; multicomponent absorption; mechanism and model of absorption with chemical reaction; thermal effects in absorption process.

Unit II: Distillation

Vapour liquid equilibria – Raoult’s law, vapor-liquid equilibrium diagrams for ideal and non-ideal systems, enthalpy concentration diagrams. Principle of distillation – flash distillation, differential distillation, steam distillation, multistage continuous rectification, Number of ideal stages by Mc.Cabe – Thiele method and Ponchan – Savarit method, Total reflux, minimum reflux ratio, optimum reflux ratio. Introduction to multi-component distillation, azeotropic and extractive distillation.

Unit III: Liquid-Liquid Extraction

Liquid-liquid extraction – solvent characteristics-equilibrium stage-wise contact calculations for batch and continuous extractors- differential contact equipment-spray, packed and mechanically agitated contactors and their design calculations-packed bed extraction with reflux. Pulsed extractors, centrifugal extractors-Supercritical extraction.

Unit IV: Leaching

Solid-liquid equilibria- leaching equipment for batch and continuous operations, calculation of number of stages – Leaching – Leaching by percolation through stationary solid beds, moving bed leaching, counter current multiple contacts (shank’s system), equipment for leaching operation, multi-stage continuous cross current and countercurrent leaching, stage calculations, stage efficiency.

Unit V: Adsorption, Ion Exchange And Membrane Separation Processes

Adsorption – Types of adsorption, nature of adsorbents, adsorption equilibria, effect of pressure and temperature on adsorption isotherms, Adsorption operations – stage wise operations, steady state moving bed and unsteady state fixed-bed adsorbers, breakthrough curves. Principle of Ion exchange, techniques and applications. Solid and liquid membranes; concept of osmosis; reverse osmosis; electro dialysis; ultrafiltration.

Text Books:

- Treybal, R.E., “Mass Transfer Operations “, 3rd Edn., McGraw-Hill,2017.

- Geankoplis, C.J., “Transport Processes and Unit Operations”, 4th Edition, Prentice Hall Inc., New Jersey, 2003.

- Wankat, P., “Equilibrium Stage Separations”, Prentice Hall, 1 998.

- B. K. Dutta.,” Mass Transfer and separation processes, Prentice Hall,2006

References:

- McCabe, W.L., Smith, J.C., and Harriot, P., “Unit Operations in Chemical Engineering”, 7th Edition, McGraw-Hill, 2017.

- Seader J.D. and Henley E.J., “Separation Process Principles”, 2nd Ed., John Wiley, 2006.

- King, C.J., “SeparationProcesses“,2ndEdn., TataMcGraw-Hill 1980.

Related Post: