In this article subject code AI3601 deals with the Post-Harvest Technology Syllabus of Anna University B.Tech Agricultural Engineering syllabus, Regulation 2021. This will help you to understand the academic syllabus well in one place.

We include the unit-wise syllabus in this article AI3601 – Post-Harvest Technology Syllabus, to help the students get a detailed syllabus of this subject. Having a good knowledge of the topics in the syllabus of this subject, helps you to make your effective notes and strategies before someone else does from your fellow friends. This will simplify your process of searching for syllabi. Including the reference books and the required textbooks to read. The following article will help you to guide the syllabus unit-wise. Hoping this information is useful to you. Kindly share it with your classmates.

If you want to know more about the syllabus of B.Tech Agricultural Engineering connected to an affiliated institution’s four-year undergraduate degree program. We provide you with a detailed Year-wise, semester-wise, and Subject-wise syllabus in the following link B.Tech Agricultural Engineering Syllabus Anna University, Regulation 2021.

Aim Of Objective:

The students would be exposed to fundamental knowledge in engineering properties of agricultural materials, different Post Harvest operations and processing methods of harvested crops and storage of crops.

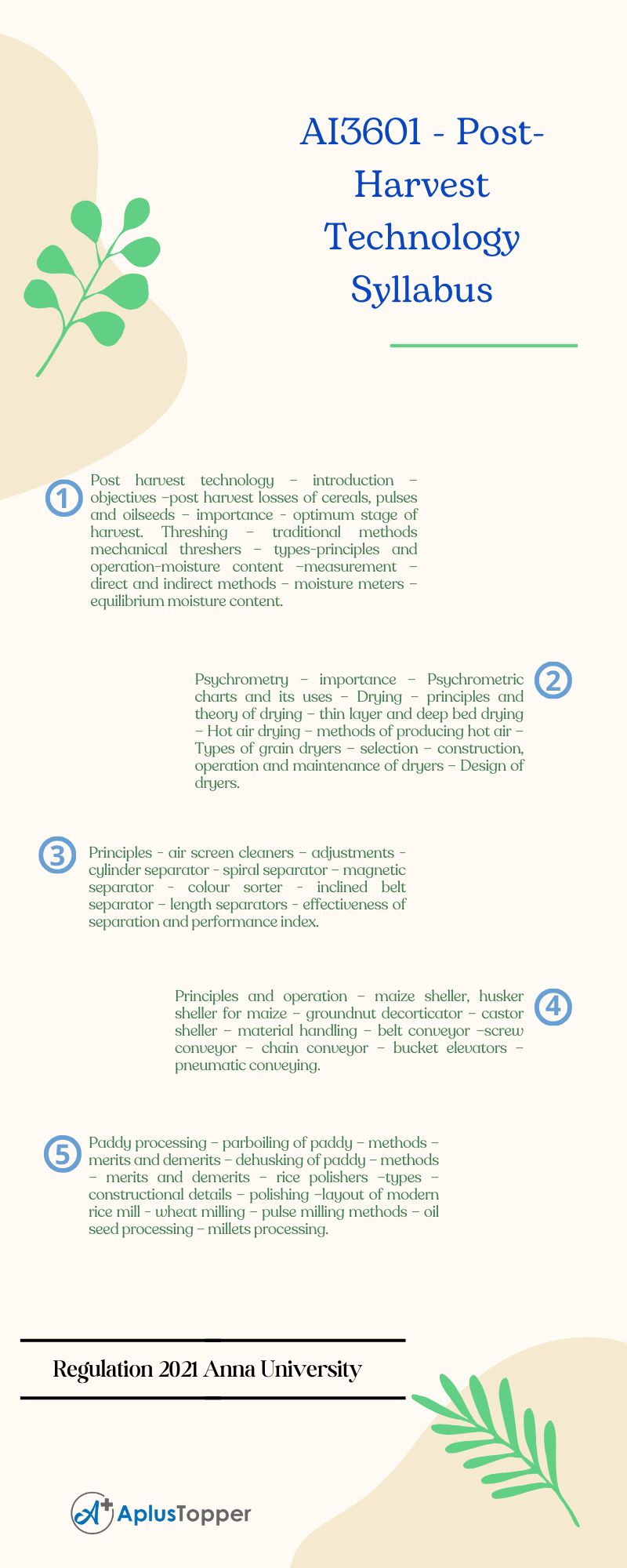

AI3601 – Post-Harvest Technology Syllabus

Unit I: Fundamentals Of Post Harvesting

Post harvest technology – introduction –objectives –post harvest losses of cereals, pulses and oilseeds – importance – optimum stage of harvest. Threshing – traditional methods mechanical threshers – types-principles and operation-moisture content –measurement –direct and indirect methods – moisture meters – equilibrium moisture content.

Unit II: Psychrometry And Drying

Psychrometry – importance – Psychrometric charts and its uses – Drying – principles and theory of drying – thin layer and deep bed drying – Hot air drying – methods of producing hot air – Types of grain dryers – selection – construction, operation and maintenance of dryers – Design of dryers.

Unit III: Cleaning And Grading

Principles – air screen cleaners – adjustments – cylinder separator – spiral separator – magnetic separator – colour sorter – inclined belt separator – length separators – effectiveness of separation and performance index.

Unit IV: Shelling And Handling

Principles and operation – maize sheller, husker sheller for maize – groundnut decorticator – castor sheller – material handling – belt conveyor –screw conveyor – chain conveyor – bucket elevators – pneumatic conveying.

Unit V: Crop Processing

Paddy processing – parboiling of paddy – methods – merits and demerits – dehusking of paddy – methods – merits and demerits – rice polishers –types – constructional details – polishing –layout of modern rice mill – wheat milling – pulse milling methods – oil seed processing – millets processing.

Textbooks:

- Chakraverty, A. Harvest technology for Cereals, Pulses and oilseeds. Oxford & IBH publication Pvt Ltd, New Delhi, Third Edition, 2000.

- Sahay, K.M., and Singh, K.K. Unit operations of Agricultural Processing. Vikas Publishing House Pvt. Ltd., New Delhi, 1994.

References:

- Pande, P.H. Principles of Agriculture Processing. Kalyani Publishers, Ludhiana, 1994.

- Henderson, S.M. and R.L. Perry. Agricultural Process Engineering. John Wiley and Sons, New York. 1955.

You May Also Visit: